PDMS is an acronym for Polydimethylsiloxane. This polymer has extensive applications in the manufacturing of microfluidic devices. PDMS exhibits several characteristics that make it highly sought after for various applications.

PDMS material demonstrates biocompatibility, flexibility, thermal stability, optical transparency, gas permeability, low cost, corrosion resistance, and user-friendliness.

PDMS is commonly employed in biomedical devices, microfluidic systems, membranes, electronic components, sensors, and coatings.

However, PDMS has low polarity since its structure contains a methyl group. This chemical group makes it challenging for PDMS to bond with molecules or liquids.

Therefore, this article will highlight how oxygen plasma treatment is used for surface activation of PDMS in microfluidic devices.

As we look at how polydimethylsiloxane (PDMS) improves microfluidic devices, we can see that its unique qualities play an essential role in the growth of this fast-changing area.

PDMS, or polydimethylsiloxane, is a synthetic polymer with many applications that cut across multiple industries. It is used for manufacturing microfluidic chips, food additives, lubricants, sponges, and anti-foaming agents.

PDMS is a unique kind of polymer because it contains carbon and silicon. It is biocompatible, resistant to chemicals, flexible, and transparent.

PDMS is considered the best option for microfluidic devices. It is famous for its use in diagnostic tools, organ-on-chip systems, and lab-on-chip devices.

Other applications of PDMS include cell culture, single-cell analysis, synthesis of drug compounds, and amplification of nucleic acid.

PDMS possesses a non-polar structure responsible for its weak interaction with external materials. The methyl group present in its structure is responsible for its hydrophobicity.

Without any enhancements, PDMS negates bonding with coatings and substrates. This polymer is subjected to surface enhancement before being used for specific applications.

To understand the interactions and enhancements within microfluidic systems, it is essential to examine how oxygen plasma treatment effectively activates PDMS surfaces.

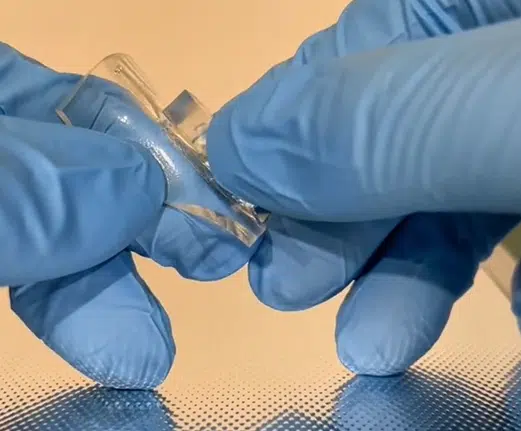

Surface activation of PDMS is all about improving how PDMS materials bond or attach to other material surfaces.

PDMS Plasma processing starts with oxidizing its surface with oxygen plasma to eliminate all impurities. This plasma process creates and deposits a particular chemical group known as silanol on the surface of PDMS.

This chemical group increases the wetness potential of PDMS, increasing its bonding strength with other materials.

Surface activation collapses the existing methyl group in PDMS’s structure, replacing it with a group that increases its polarity.

This functional group combines with the PDMS surface molecules to remove organic and inorganic contaminants.

Surface energy is another factor that determines whether a specific material will be more hydrophilic or hydrophobic.

Plasma enhances the wetness potential of PDMS by realigning its molecules to improve surface energy.

This is one of the mind-blowing advantages of plasma treatment on PDMS. Plasma treatments enhance the surface properties of PDMS.

However, while surface chemistry alteration is possible with plasma, the new surface structure can last for a specific period.

It is possible to reverse the surface activation if that need ever arises. On the other hand, if you prefer to extend the surface activation of PDMS, there are steps to achieve that.

Given the numerous advantages that plasma-treated PDMS brings to microfluidic applications, it’s important to highlight the various industries that are reaping the benefits of this innovative technology.

Plasma-enhanced PDMS brings vast improvements to microfluidic devices. It ensures enhanced bonding for microfluidic chips used in diagnostic assays. This translates to high-quality devices and safer medical procedures.

PDMS is also advancing biotechnology applications. Plasma treatment helps to enhance the surface molecules of PDMS.

PDMS treated by plasma improves adhesion in organ-on-chip and tissue engineering applications.

The pharmaceutical industry is maximizing plasma-enhanced PDMS for various applications. Plasma treatment enhances PDMS, removing surface contaminants to ensure cleanliness.

The rearrangement of PDMS molecules causes an increase in surface energy and wetness potential. Plasma-enhanced PDMS guarantees reliable bonding for drug delivery systems and analytical devices.

To fully appreciate the impact of oxygen plasma treatment on microfluidic applications, examining its specific benefits for PDMS, enhancing device functionality and reliability is important.

Untreated PDMS creates a weak bond when in contact with other material surfaces. The non-polar nature of PDMS is responsible for the weak attachment with foreign items.

Plasma can be used to correct this anomaly. Plasma cleaning helps rearrange PDMS molecules, making its surface more receptive to incoming elements. This development automatically results in stronger bond formation.

With stronger bonds, PDMS becomes further enhanced for microfluidic devices, ensuring improved adhesion to glass, silicon, and other microfluidic substrates.

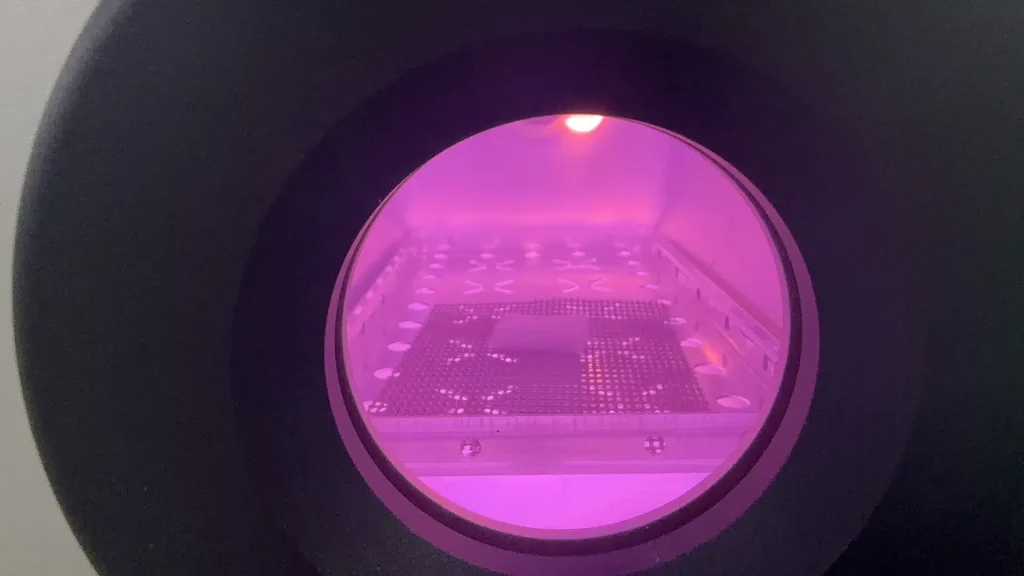

Microfluidic devices are performing better today with PDMS materials treated with plasma. Plasma cleaning is a game changer in the manufacturing of various microfluidic devices.

PDMS materials enhanced with plasma provide better sealing, durability, and precision in microfluidic channels and layers.

Microfluidic devices are much more reliable and accurate, thanks to plasma processes that can improve the nature of PDMS.

Plasma is the choice of most manufacturers because of its non-use of chemicals. Unlike conventional cleaning methods that use toxic chemicals for priming surfaces, plasma uses reactive species to enhance surface characteristics.

Plasma treatment is also friendlier to the environment since it does not leave any chemical waste behind.

There are dozens of environmental benefits to using plasma to treat PDMS surfaces at the expense of traditional methods.

Biocompatibility is an essential quality of microfluidic devices. If a material is incompatible with human biology, that material cannot be used to create medical devices.

Plasma cleans PDMS material surfaces, eliminating all contaminants by influencing the arrangement of surface molecules. Plasma treatment ensures clean, safe surfaces suitable for biological and medical applications.

To illustrate the practical applications and successes of plasma treatment in microfluidic devices, let’s explore a series of case studies that highlight the effectiveness of this technique with PDMS.

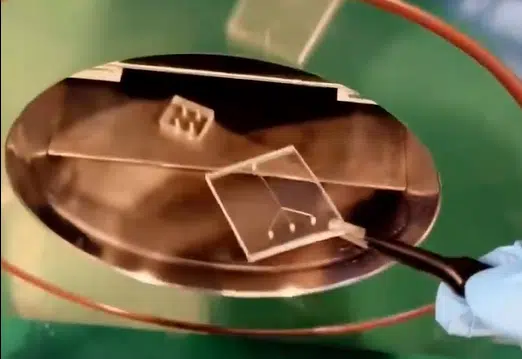

A lab-on-a-chip device is used mainly to distinguish between blood and plasma. Such medical devices are cheap, portable, and precise. They can also provide quick results for medical examinations.

Lab-on-a-chip devices are used for different applications, such as food safety, chemical analysis, and healthcare.

Plasma-treated PDMS has been a significant boost to the manufacture of microfluidic devices. It has made it possible to achieve reliable and leak-proof bonds in diagnostic tools.

These systems behave like human organs by functioning and having similar physiological environments as humans.

They are used in simulating diseases and predicting how the causative organisms will respond to drugs.

Organ-on-a-chip or OoC applications extend to drug discovery, disease modelling, multiple organ systems, and models based on patients.

PDMS-treated by plasma has caused the rapid advancement of OoC systems. It ensures improved cell adhesion and compatibility for tissue engineering.

Plasma enhances drug delivery systems made from PDMS or any other natural polymer. It does that by improving the properties of the material.

Plasma improves the way PDMS interacts with cells, tissues, and drugs. It enhances the loading and release of drugs.

Plasma is also responsible for making drug delivery systems more biocompatible with humans. Plasma treatment enforces stronger bonding for precise microfluidic channels in pharmaceutical devices.

As we delve into the techniques for maximizing the effectiveness of plasma treatment, it becomes crucial to focus on the strategies for optimizing this process in PDMS applications within microfluidics.

Using plasma treatment machines with recommended parameters is crucial for optimizing PDMS surface enhancements.

Some parameters must be tweaked accordingly to arrive at specific outcomes of surface chemistry alteration. Use the suggested power, pressure, and duration for effective PDMS surface activation.

Plasma treatment is an oxidation process that improves PDMS in several ways and makes it suitable for some medical applications.

However, excess oxidation must be avoided when treating polymers like PDMS with plasma. Over-exposure can lead to surface degradation and other more severe consequences.

Consider the PDMS outcome you hope to achieve and expose the material to plasma for the required time.

Allowing the PDMS to stay inside the chamber for longer than expected will be counterproductive for the process.

How long the effect of a surface activation process can last on PDMS materials depends on a set of factors.

And while the activation time can last for a reasonable length of time, you can take extra steps to extend the effect on the PDMS material. Employ techniques like immediate bonding or using salinization to maintain surface activation.

It is essential to consider the emerging trends in plasma treatment that promise to drive innovation and enhance the capabilities of microfluidic technologies.

Plasma treatment microfluidic devices are getting better with each passing day. The future is exceptionally bright, with numerous advanced device designs on the horizon.

Some of the current advancements include the development of multi-material microfluidic systems using plasma-treated PDMS. Expect designs that will enhance the precision, functionality and quality of microfluidic devices.

Manufacturers also look forward to incorporating plasma machine features to handle automation for repeated processes.

Such additions will lead to more accurate results and better reliability of microfluidic devices made from PDMS.

PDMS is chosen among many polymers as a suitable option for manufacturing microfluidic devices. PDMS has applications that span beyond the field of medicine and pharmaceuticals.

This article explains how oxygen plasma treatment is redefining the application scope of PDMS as it concerns medical devices. It is increasing its usefulness by altering surface chemistry.

Choose a suitable plasma treatment machine today to help you with the surface activation of PDMS in microfluidic devices.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate