In modern manufacturing, adhesion is everything. Whether you're bonding two materials together, applying a coating, or preparing a substrate for lamination, poor adhesion can spell disaster for product quality and reliability. Yet many manufacturers still struggle with weak bonds, delamination, and coating failures that cost time and money.

The solution? Plasma surface activation.

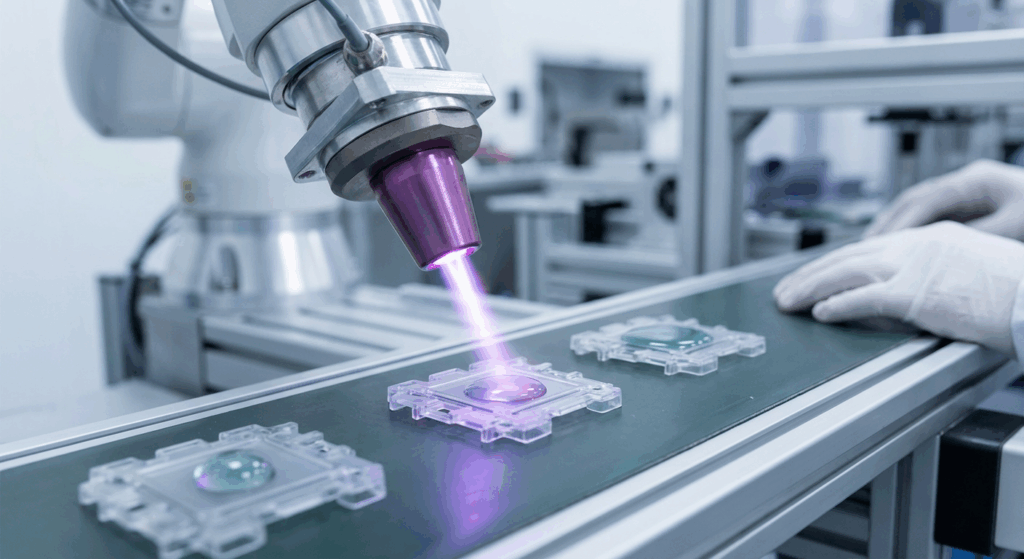

Plasma surface activation has revolutionized how manufacturers prepare materials before bonding or coating processes. By fundamentally changing the physical and chemical properties of a surface at the molecular level, plasma technology creates ideal conditions for adhesion. At Fari Plasma, we've spent years helping manufacturers across industries solve their most stubborn adhesion challenges using advanced plasma treatment systems.

Before we dive into plasma solutions, let's understand why adhesion is so challenging in the first place.

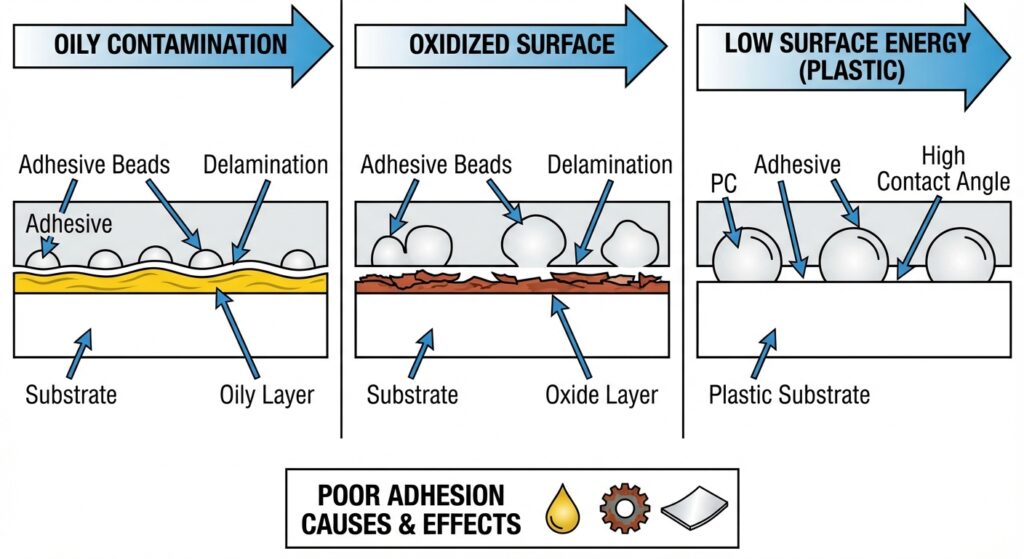

When two materials meet, they don't simply stick together like you might imagine. Adhesion is a molecular phenomenon. For a strong bond to form, the molecules of different materials must come into intimate contact. But here's the problem: most manufactured surfaces are contaminated, oxidized, or chemically inert—conditions that actively prevent strong adhesion.

Consider a plastic polymer surface. Its molecular structure often includes non-polar groups that naturally repel adhesives and coatings. Add surface contamination like dust, oils, or factory residues, and you've created an environment where adhesion is nearly impossible.

Traditional surface preparation methods—like mechanical abrasion, solvent wiping, or grinding—can help, but they're often:

This is where plasma surface activation changes everything.

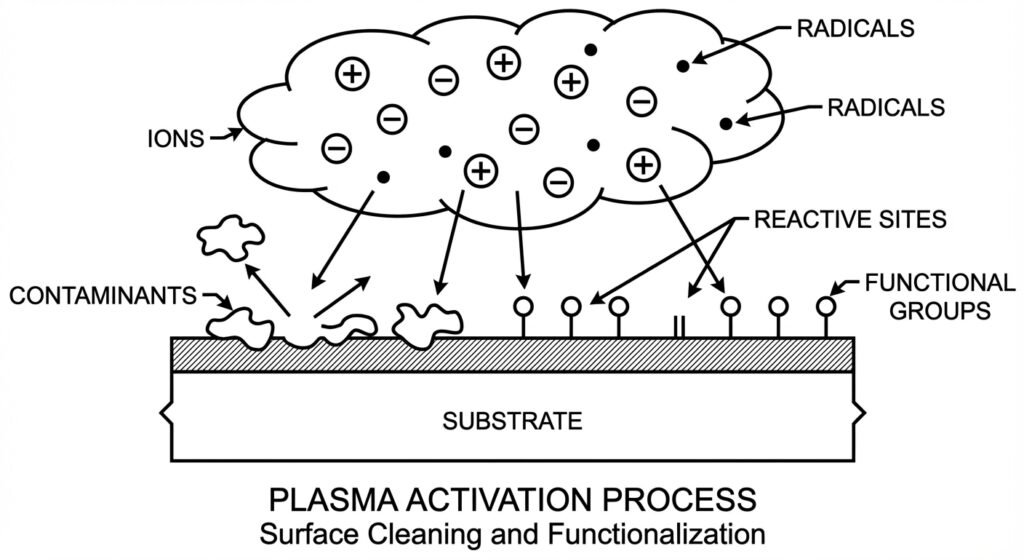

Plasma is often called the fourth state of matter. While solids, liquids, and gases are familiar to most people, plasma is an ionized gas containing free electrons, ions, and reactive neutral particles. When energy is applied to a gas, its atoms become ionized, creating this energetic state.

In plasma surface activation, this ionized gas is carefully controlled and directed at the surface of a material. The plasma doesn't melt or significantly damage the substrate. Instead, it interacts with the surface at the molecular level, creating profound changes in how that surface behaves.

When plasma contacts a material surface, several critical reactions occur:

1. Physical Cleaning: The energetic ions physically bombard the surface, removing loose contaminants, oxidized layers, and organic residues. This cleaning occurs without harsh chemicals or mechanical damage.

2. Chemical Modification: The reactive species in plasma—including free radicals, ultraviolet radiation, and metastable atoms—chemically transform the surface. These reactions create new functional groups like hydroxyl (−OH), carboxyl (−COOH), or amine (−NH2) groups, depending on the plasma chemistry used.

3. Surface Roughening: Plasma etching increases surface roughness at the microscopic level. This creates more surface area and improves mechanical interlocking with adhesives or coatings.

4. Crosslinking Enhancement: In some applications, plasma treatments promote crosslinking reactions that strengthen the surface layer itself.

The result? A surface that's chemically reactive, mechanically receptive, and perfectly primed for adhesion.

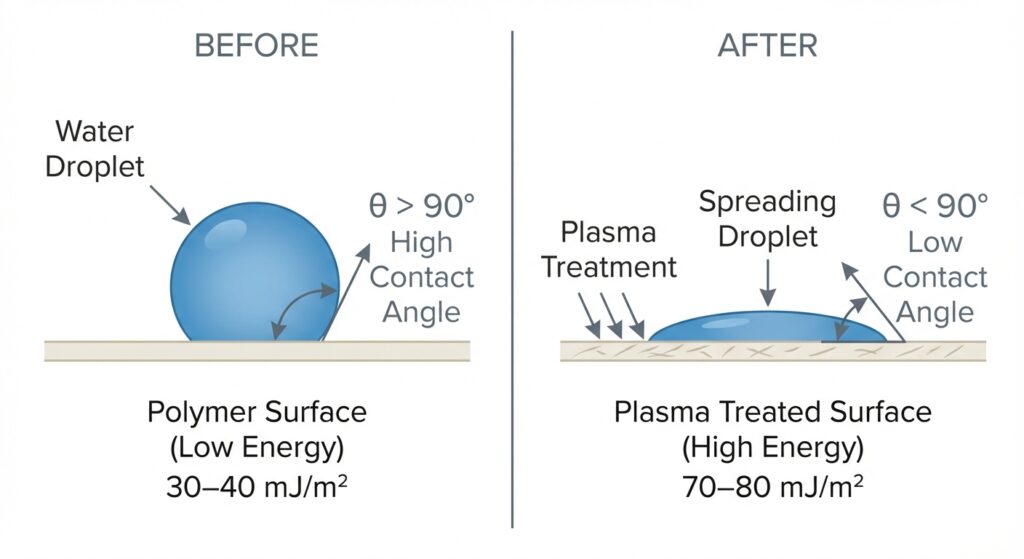

One of the most important concepts in adhesion is surface energy (also called surface tension). Materials with high surface energy are "wettable"—they allow liquids like adhesives and coatings to spread across them rather than beading up like water on a freshly waxed car.

Most materials that require bonding—plastics, rubbers, composites, films—naturally have low surface energy. Adhesives and coatings have a hard time spreading evenly across these surfaces, creating weak, incomplete coverage.

Plasma treatment dramatically increases surface energy. By introducing polar functional groups to the surface, plasma makes the material more attractive to adhesive molecules. The adhesive spreads uniformly, creating complete coverage and superior bonding strength.

Studies have shown that plasma activation can increase surface energy from 30−40mJ/m2 (poorly wettable) to 70−80mJ/m2 or higher (highly wettable) in seconds.

Even surfaces that look clean contain invisible contamination: silicone mold release agents, fingerprints, dust particles, and oxidized layers. These contaminants form a barrier between the substrate and the adhesive, creating a predictably weak bond.

Plasma removal of contaminants is thorough and gentle. The energetic ions remove contamination without the aggressive mechanical action that can damage delicate materials or the chemical residues that solvent cleaning can leave behind.

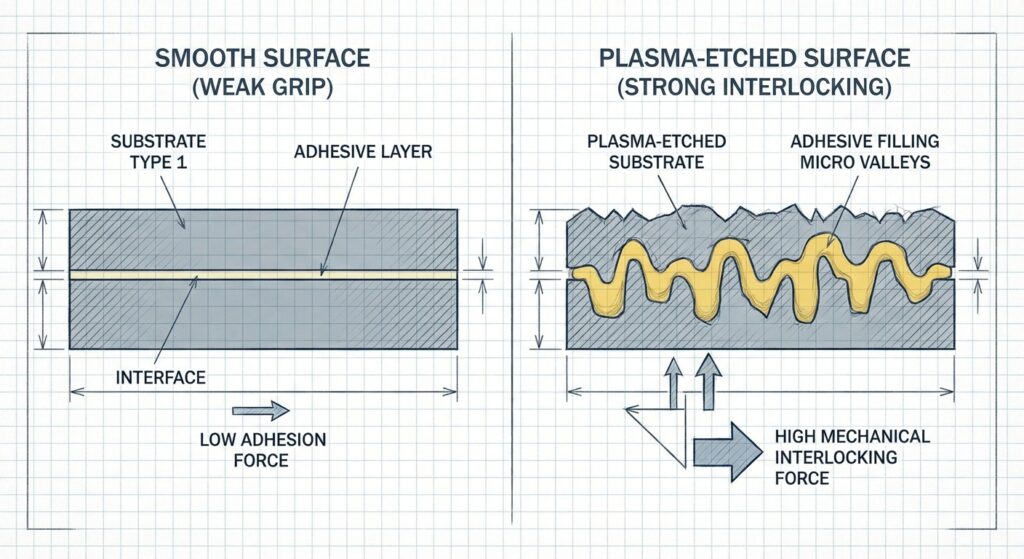

At the microscopic level, adhesive strength depends partly on mechanical interlocking. Imagine trying to glue two polished glass panes together versus two sheets of sandpaper—the rougher surface allows for better mechanical grip.

Plasma treatment creates controlled surface roughness through etching. This isn't random damage; it's a uniform increase in microscopic texture that provides numerous anchor points for adhesive molecules. This mechanical component significantly contributes to the overall bond strength.

In semiconductor and electronics manufacturing, adhesion challenges are particularly critical. Plasma surface activation is essential for:

Our semiconductor plasma equipment can treat complex 3D structures and maintain the ultra-high cleanliness standards that electronics manufacturing demands.

Medical devices require exceptional reliability. Plasma surface activation ensures:

Plasma treatment is particularly valuable because it's a dry, chemical-free process compatible with medical device sterility requirements.

Composite bonding in aerospace demands extreme reliability:

The consistency that plasma provides is invaluable in aerospace, where process validation and repeatability are essential.

Automotive applications benefit from plasma activation in:

The packaging industry relies on consistent, strong adhesion:

Modern plasma surface activation systems come in several configurations, each suited to different manufacturing scenarios:

These systems treat multiple components in a chamber, ideal for:

Batch systems offer flexibility and comprehensive surface treatment but have lower throughput than inline systems.

For high-volume manufacturing, inline plasma systems integrate directly into production lines:

Specialized plasma equipment for semiconductor applications handles:

Unlike manual surface preparation methods, plasma systems deliver consistent results. The process parameters—gas type, pressure, power, and time—can be precisely controlled, ensuring every component receives identical treatment. This repeatability is critical for manufacturing quality and regulatory compliance.

Plasma activation happens in seconds to minutes, making it practical for production environments. Combined with no drying time or complex fixturing, plasma treatment adds minimal time to manufacturing cycles.

Plasma is a dry, chemical-free process. There's no solvent waste, no chemical disposal requirements, and minimal environmental impact. This makes plasma activation increasingly attractive to manufacturers committed to sustainable manufacturing practices.

While plasma equipment represents an investment, the return comes through:

For manufacturers processing significant volumes, the cost per unit treated becomes negligible compared to the value of improved adhesion and reduced failures.

Plasma activation works on an enormous range of materials:

This versatility makes plasma systems valuable across diverse manufacturing environments.

Plasma-activated surfaces are most reactive immediately after treatment. The window of opportunity typically spans from minutes to several hours, depending on the material and environment. Best practices include:

Different gases produce different surface chemistries:

Selecting the appropriate gas chemistry for your specific application maximizes adhesion benefits.

To maximize benefits, establish clear process parameters:

Successful plasma integration considers:

After plasma treatment, some materials can re-oxidize in air. This is particularly true for metals and some polymers. Solutions include:

Some sensitive materials can be affected by aggressive plasma treatment. Solutions include:

For manufacturers skeptical about investment, establish clear metrics:

Plasma technology continues to evolve:

Plasma surface activation represents a fundamental shift in how manufacturers approach adhesion challenges. By transforming surfaces at the molecular level, plasma technology enables stronger bonds, more reliable products, and more efficient manufacturing processes.

Whether you're struggling with weak adhesion in existing processes or developing new products that require exceptional bonding, plasma surface activation offers proven, scientifically-backed solutions. The combination of consistency, speed, environmental benefits, and measurable improvements in adhesion strength makes plasma treatment an essential technology for modern manufacturing.

At Fari Plasma, we've helped manufacturers across industries implement plasma surface activation systems tailored to their specific needs. Our expertise in plasma cleaner technology, plasma treatment systems, and semiconductor plasma equipment means we understand the unique challenges different industries face.

If adhesion is holding back your manufacturing performance, it's time to discover what plasma surface activation can do for you. The surface of your success starts here.

About Fari Plasma: We manufacture advanced plasma equipment including plasma cleaners, plasma treatment systems, and specialized semiconductor plasma equipment. Our solutions help manufacturers achieve superior adhesion, improve product quality, and streamline production processes across industries worldwide.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate