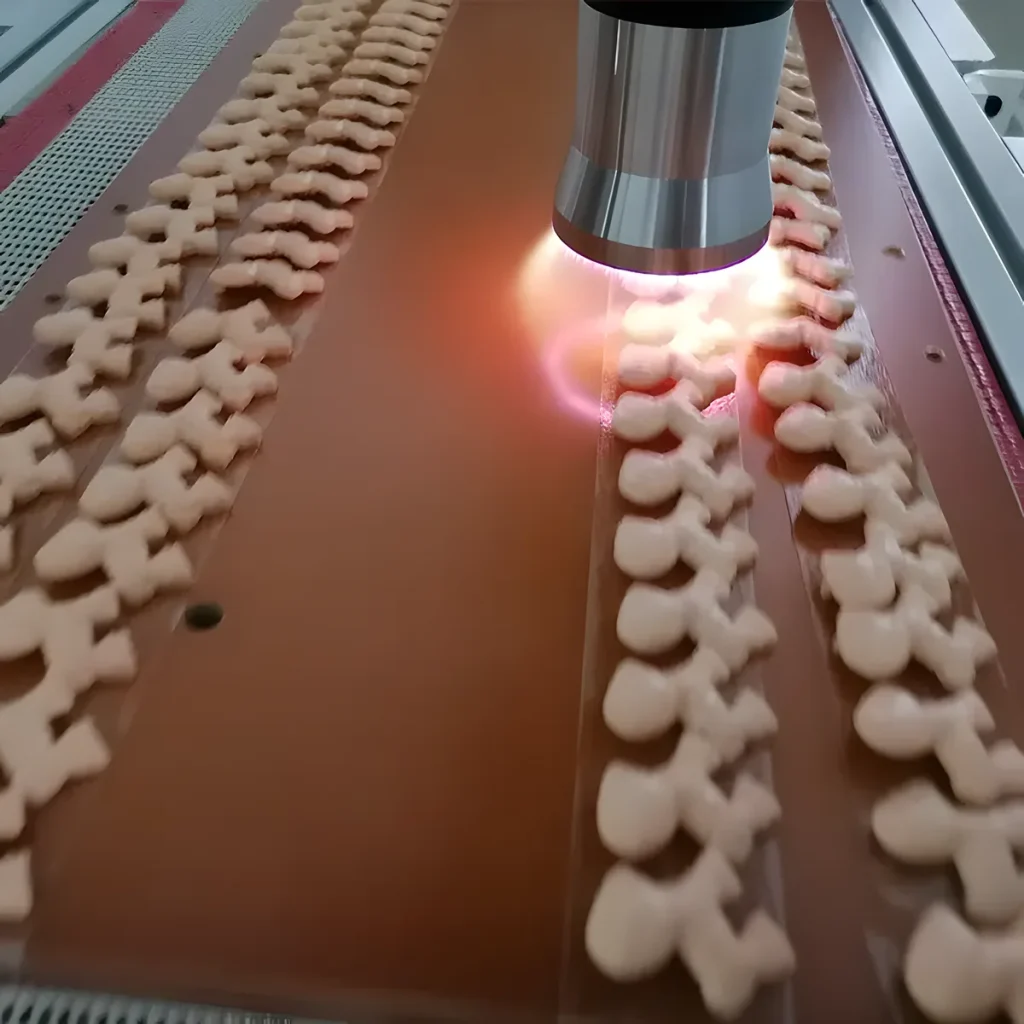

PM-G13A Atmospheric plasma treatment machine is a portable device, it is just about 30 kg. It is single nozzle for treatment width 35-80 mm. When using plasma , you can connect the nitrogen or compressed air according to your need. In general, compressed air can reach good effect for almost material. But for some particular material, nitrogen can get better effect. PM-G13A plasma treater can combine with conveyor to reach high productivity.

ABS plastic is widely used in a variety of fields, which the largest application fields are automotive, electronics, toys, building materials and DIY production fields, they are processed into all kinds of products through bonding, printing, spraying, electroplating and other processes.

However, because the critical surface tension of ABS is relatively low, probably between 34 and 38 mN / cm, the activation treatment should be performed on its surface before these processes.

For example, when ABS is bonded, it is difficult for the adhesive to closely fit with the surface. After the plasma treatment, the adhesive wetting area can be greatly increased, and an active layer is formed on the surface, so that ABS plastic can be bonded very well. Therefore, for printing, spraying, bonding, which requires the material adhesion, the use of plasma cleaning technology can improve the surface activity and complete the product process production.

About the electroplating of ABS, Its process should go through oil removal, organic solvent pre-coarsening, chromic acid coarsening, activation, pre-plating, electroplating, this process will cause harm to both the environment and the human body. Choosing a plasma surface processor to replace it, which can save the use of organic solution and reduce the pollution damage.

Here are some advantages about the atmospheric plasma cleaning technology:

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate