Plasma cleaning is a common surface treatment technique that can change the physical and chemical properties of the material surface and improve the hydrophilicity, adhesion and bonding of the material. The effect evaluation and determination of plasma treatment is very important for the applicability of products in practical application. This paper will introduce some common test methods after plasma treatment.

Plasma treatment can change the micromorphology of the material surface, such as roughness, texture, etc. We can evaluate the effect of the treatment on the surface morphology after the treatment. Commonly used surface morphology observation instruments include electron microscope (EM), optical microscope (OM), more professional, including atomic force microscope (AFM) and transmission electron microscope (TEM), etc

Plasma cleaning can change the chemical composition of the surface of materials, such as increasing the surface polarity, introducing active groups, etc. Through surface composition analysis, we can understand the influence of plasma treatment on the chemical composition of the surface. Common surface composition analysis methods include X-ray photoelectron spectroscopy (XPS), infrared spectrum (IR) and chemical analysis.

Surface wettability is the ability to expand and attach on a solid surface. The altered infiltration of the material surface treated by a plasma washer improves the hydrophilicity and adhesion of the surface. The effect of plasma treatment on the surface infiltration can be assessed by measuring the contact angle size of water droplets before and after treatment, usually using the water drop angle tester, and the smaller the contact angle, the better the infiltration. In addition, other test methods, such as hanging drop method, titration method, can be used to evaluate the surface infiltration. Through visual observation, if the water droplets can be quickly spread on the surface, it can be concluded that the wettability of the material surface has been significantly improved.

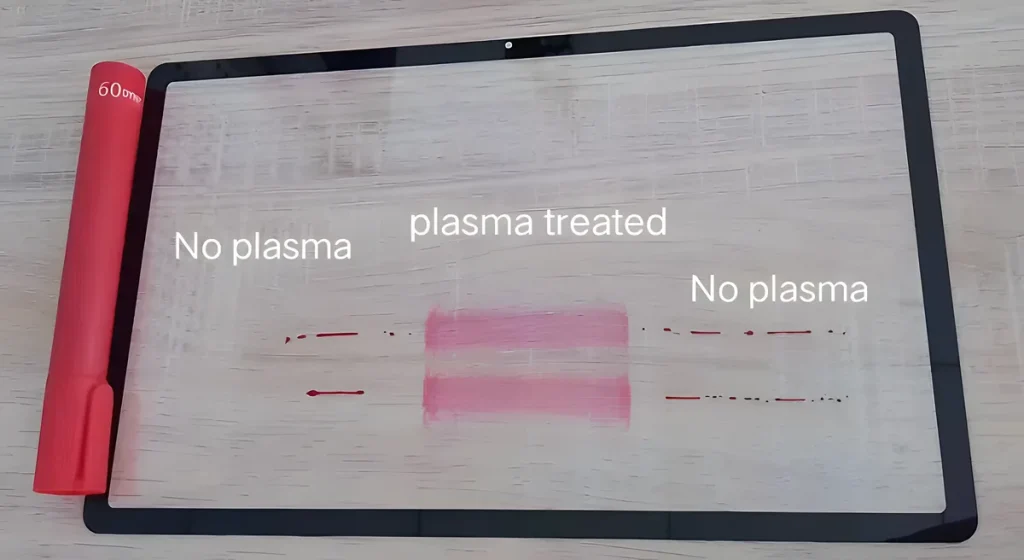

The size of surface tension plays a decisive factor in adhesion, and bonding, welding, spraying and other processes are closely related to the size of adhesion. Plasma plays a key role in improving the adhesion of the material. Therefore, the change of the surface adhesion can be known by measuring the size of the tension value. Generally, the tension of the material can be tested. Each pen has a different single value, which can measure the tension range of 28 to 72 m N/m, and the color is blue-purple, pink, blue and green. When the wire detection is used, when the surface tension of the material is equal to or greater than the value of the pen, the line can be drawn. By judging the state of the ink painting, we can roughly estimate the tension range of the surface of the material.

For some biomedical applications, plasma treatment can improve the biocompatibility of material surfaces and reduce inflammatory responses and thrombosis in living organisms. The biocompatibility test evaluates the impact of plasma surface cleaning on the ability of the material surface to interact with the organism. Commonly used biocompatibility test methods include cell culture test, in vivo animals, etc. In conclusion, the test methods after plasma treatment include microscopy, composition analysis, infiltration tests, tension tests, and biocompatibility tests. Through these test methods, we can evaluate the influence of plasma cleaning technology on the surface properties of materials, and provide an important reference basis for practical applications.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate