Solar panels are made with reflective films to enhance light absorption, reduce glare, and improve energy efficiency.

The solar panels change the sun’s energy into electricity, whereas the reflective films regulate heat and glare.

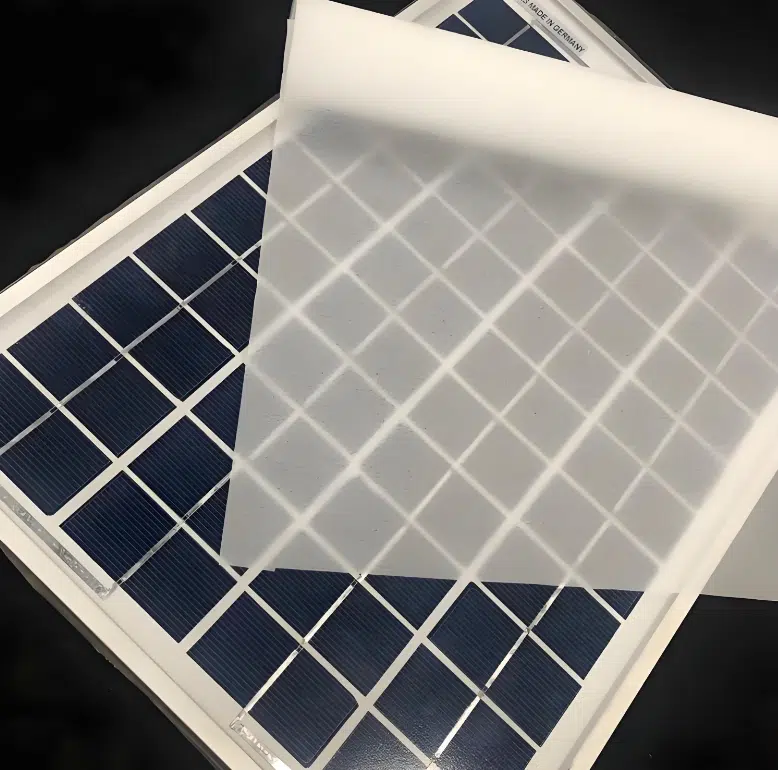

Effective adhesion of reflective film on solar panels is necessary to ensure durability and performance.

However, reflective films may have some challenges, such as poor adhesion due to contaminants, low surface energy, and material incompatibilities. Fortunately, such challenges can be addressed with plasma solutions.

Plasma cleaning offers a precise, eco-friendly solution for surface preparation to enhance film adhesion on solar panels.

Understanding how these films contribute significantly to enhancing light absorption, regulating heat, and reducing glare is important.

Reflective films are micro-thin coatings of metal layer with a mirror-like finish. Thin layers are applied to solar panels to reflect and redirect sunlight for maximum energy capture.

Reflective films prevent visibility from outside when it’s day and vice-versa at night. These films are commonly made from PET, PMMA, or polycarbonate materials.

It is necessary to employ adhesives on solar panels to ensure the film remains intact under environmental stresses such as temperature fluctuations, UV exposure, and moisture.

Performance and durability are enhanced when the reflective film bonds properly to the solar panel surface.

Reflective films have certain limitations when it comes to adhering to solar panels. They form weak bonds on solar panel surfaces because of low surface energy and contamination. As such, it can cause films to delaminate or peel under prolonged exposure to outdoor conditions.

Plasma cleaning enhances adhesion by transforming surface preparation, improving material bonding, and driving innovations in various industrial applications.

Plasma surface treatment utilizes ionized gas to clean and activate material surfaces, enhancing adhesion properties effectively.

This eco-friendly process efficiently removes contaminants, modifies surface energies, and improves bonding potential for coatings, adhesives, or paints. Ideal for diverse applications.

Plasma cleaning employs three major mechanisms when employed on material surfaces.

It uses surface cleaning, surface activation, and micro-structuring to improve surface characteristics, making them suitable for various applications.

Through surface cleaning, plasma cleaning removes organic contaminants, oils, and residues.

It employs surface activation to introduce polar functional groups (e.g., hydroxyl, carboxyl) to increase surface energy.

And with the help of micro-structuring, plasma cleaning can create nanoscale roughness for improved mechanical interlocking.

Plasma cleaning brings several advantages when used on solar panels. Some benefits of plasma on solar panels include ensuring that the solar panel materials are non-destructive and compatible with sensitive materials. Another advantage is that plasma is an eco-friendly alternative to chemical primers.

Exploring the benefits of plasma cleaning for reflective film adhesion reveals its potential to improve performance and longevity in solar panel applications significantly.

Plasma treatment enhances the adhesion strength and durability of reflective films by cleaning surfaces and increasing their surface energy.

This process ensures optimal bonding by removing contaminants and creating a more receptive surface, leading to longer-lasting and reliable reflective film applications.

Plasma treatment preserves reflective films’ integrity by ensuring optimal adhesion, preventing delamination, and maintaining surface smoothness.

This improves light redirection and energy efficiency, offering durable performance without surface degradation or adhesive failure, ensuring long-term effectiveness..

Plasma treatment enhances the resistance of reflective films to peeling and delamination by creating a robust bond between the film and substrate.

This process increases adhesion, effectively withstanding harsh environmental conditions such as moisture, temperature fluctuations, and UV exposure for lasting performance.

Plasma cleaning minimizes the need for chemical treatments by using ionized gas to cleanse surfaces effectively.

This eco-friendly process supports sustainability by cutting chemical waste and emissions, saving resources, and encouraging safer, greener production methods in many industries.

Plasma cleaning suits high-volume solar panel production by offering fast, efficient surface preparation.

Its adaptability ensures thorough cleaning without slowing down the line, enhancing panel quality and performance.

The process integrates seamlessly, supporting large-scale manufacturing goals with minimal disruption.

Looking at how we make solar panels shows that new technologies are really important for making them work better and help us use cleaner energy.

Plasma cleaning enhances film adhesion on traditional and bifacial PV panels by thoroughly cleaning and activating surfaces.

This improves layer bonding, leading to more efficient light capture and energy conversion. The process ultimately boosts panel performance and lifespan in solar applications.

Plasma cleaning ensures reliable bonding of reflective layers in sunlight-focusing systems by eliminating surface contaminants and increasing surface energy.

This results in stronger adhesion, maintaining the alignment and effectiveness of reflective surfaces, thus optimizing sunlight concentration and system efficiency.

Plasma cleaning enhances the bonding of anti-glare coatings by thoroughly preparing the surface, removing impurities, and increasing surface energy.

This ensures strong adhesion, preserving the coatings’ transparency and effectiveness, ultimately maintaining the optical clarity and efficiency of the substrate.

Delving into process optimization for plasma cleaning uncovers strategies to enhance efficiency and effectiveness, which is crucial for maintaining competitive advantages in manufacturing.

Using specific parameters for solar panel applications is crucial for optimizing plasma cleaning. Adjusting parameters like gas selection, power levels, and treatment duration helps guarantee the best results.

Using oxygen or a combination of gases is suitable for cleaning and activating surfaces. Power levels must be carefully set to prevent damage to fragile film materials. Additionally, the treatment duration should be optimized to ensure complete surface activation.

Post-treatment validation is necessary to ascertain the effectiveness of a plasma cleaning process. Use a method like Contact Angle Measurements to assess wettability improvements.

Adhesion testing can be used to test bond strength between reflective films and panel surfaces. That way, you can quickly tweak the process to get the desired results.

Integrating plasma cleaning systems into manufacturing lines allows for high-speed, uniform treatment of materials.

By fitting smoothly into the manufacturing process, plasma cleaning ensures surfaces are prepared consistently, which improves product quality and adhesion.

It does all this without interrupting the production flow, ultimately increasing efficiency and boosting output in industrial settings.

Ensuring proper plasma settings is crucial to prevent degradation or damage to reflective films and solar panel surfaces.

Appropriate settings maintain material integrity, preserving performance and lifespan. This care protects investments, maintains efficiency, and supports sustainable energy production goals.

Achieving consistent plasma exposure on large-scale panels requires advanced equipment calibration and precise process controls.

Uniform treatment ensures optimal surface preparation without variations, enhancing adhesion and performance.

Addressing this challenge is crucial for reliable results and maintaining high-quality production standards.

Buying plasma systems can cost a lot at first. But over time, they make things work better and last longer, which lowers extra costs and makes products better. So, spending money on them is worth it in the end.

Plasma cleaning ensures treated panels meet industry durability and environmental performance standards by providing thorough surface preparation.

Plasma enhances adhesion, prevents degradation, and withstands harsh conditions, leading to long-lasting, reliable panels that comply with sustainability and quality benchmarks in the industry.

Solar panels with plasma-treated reflective films demonstrate increased energy output over extended periods by providing enhanced light capture and surface integrity.

The improved adhesion and durability of treated films ensure sustained performance, maximizing energy efficiency and effectiveness in various environmental conditions.

Case studies reveal solar panels with plasma-treated surfaces exhibit reduced delamination in extreme weather.

This process strengthens adhesion, ensuring panels withstand high winds, temperature fluctuations, and moisture.

Reliable performance under harsh conditions enhances longevity and energy production efficiency in challenging climates.

Leading solar panel manufacturers integrate plasma cleaning into high-volume production to enhance surface preparation, improve adhesion, and ensure consistent quality.

This approach boosts efficiency and product reliability across large-scale manufacturing operations.

Plasma-prepared surfaces enhance the development of next-generation reflective films with self-cleaning or anti-fouling properties by optimizing adhesion and surface characteristics.

This treatment empowers innovative film technologies to maintain clarity and performance, reducing maintenance needs and improving energy efficiency in diverse applications.

AI-driven manufacturing utilizes real-time monitoring and optimization of plasma treatment parameters to ensure consistent quality.

AI analyzes data to adjust settings precisely, boosting process efficiency and reducing human error. This leads to consistent surface treatment and better product performance during solar panel production.

Expanding plasma technology in solar panel manufacturing supports eco-friendly practices by reducing chemical usage and waste.

This technology improves surface preparation with little environmental impact, supports sustainable production, boosts panel efficiency, and helps create cleaner energy solutions for a greener future.

Emerging tailored plasma cleaning processes will cater to specialized solar panel designs and applications, enhancing efficiency and performance.

These customized treatments will address specific surface needs, fostering innovation and enabling advanced solar technologies to meet future energy challenges better.

Conclusion

Plasma cleaning provides an effective and environmentally friendly solution for preparing solar panel surfaces, thereby enhancing the adhesion of reflective films.

This ensures optimal energy efficiency and longevity of solar panels by addressing challenges like contaminants and material incompatibilities.

Explore Fari Plasma’s set of high-end vacuum cleaners for cleaning and preparing solar panel surfaces.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate