Metalized plastics refer to a group of plastics that have been galvanized with a thin layer of metal.

These plastics are widely used in industries such as electronics, automotive, and packaging due to their lightweight and conductive properties.

Some of their applications include EMI shielding, decorative parts, and high-performance electronics. As a result, anti-static coatings are necessary for metalized plastics to function well.

However, the bad news is that metalized plastics normally have surface contaminants and low surface energy, which is responsible for poor bonding of anti-static coatings.

Therefore, this article discusses plasma as a precision cleaning and surface activation technique that ensures proper adhesion and performance of anti-static coatings.

To fully grasp the benefits of metalized plastics, it’s important to explore their characteristics and the challenges they face.

Metalized plastics are usually coated with a thin layer of metal, such as aluminum, copper, or chromium. The aim of producing such materials is to offer both plastic and metal benefits.

Metalized plastics are used for different applications which include decoration, shielding, and conductivity.

Residues from manufacturing processes, such as oils and mold release agents can lead to surface contamination in metalized plastics. This can make it impossible for anti-static coatings to bond effectively on their surface.

This type of plastic has a low surface energy that reduces the efficacy of anti-static coatings.

Smooth metalized surfaces are responsible for the poor surface roughness that hampers mechanical interlocking.

Diving into the role of plasma cleaning reveals how this technique addresses surface preparation challenges and enhances the performance of metalized plastics.

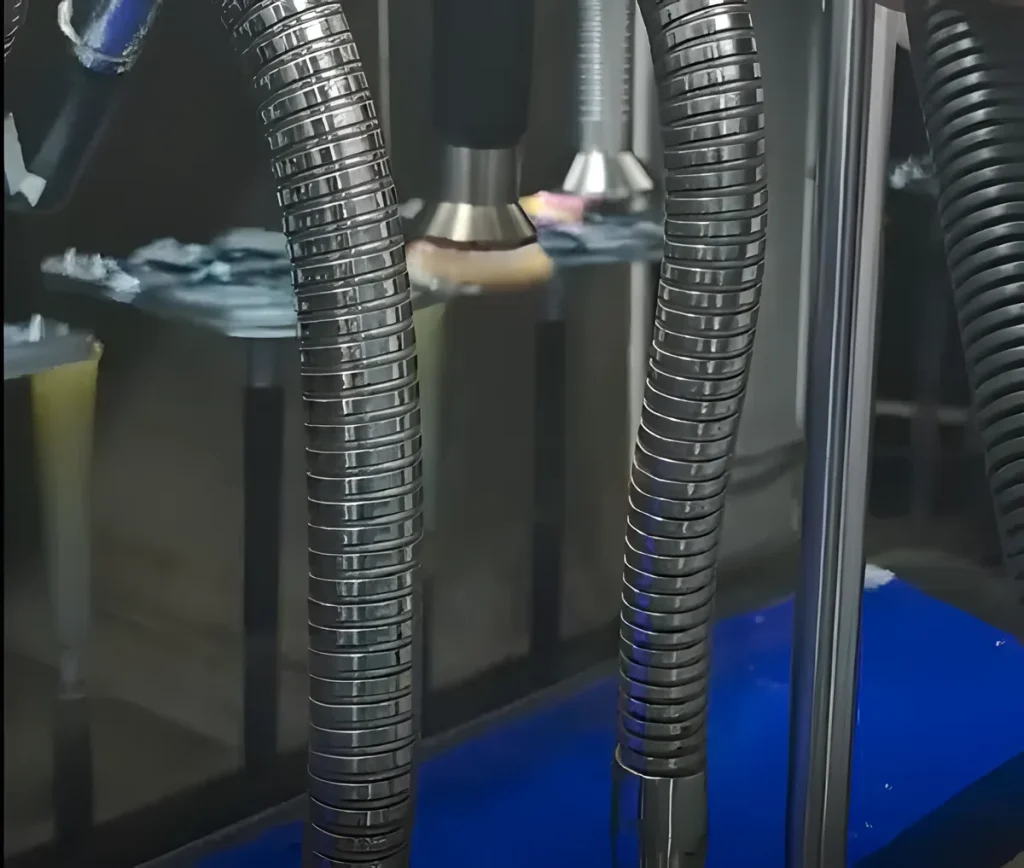

Plasma cleaning uses ionized gases to create a reactive environment that effectively removes contaminants and activates surfaces.

As a dry cleaning process, it eliminates the need for solvents by relying on charged particles to break down impurities and enhance surface properties. This makes it ideal for cleaning delicate or sensitive materials.

Plasma cleaning effectively removes organic and inorganic contaminants at the molecular level by using ionized gases.

The high-energy environment breaks down unwanted particles, ensuring thorough surface cleanliness and preparation, essential for various industrial and scientific applications.

Plasma as a surface activation method introduces polar functional groups, such as hydroxyl and carboxyl, onto material surfaces.

This increases surface energy, enhancing adhesion, wetting, and bonding properties, which is vital for coatings, adhesives, and various industrial applications.

Plasma is used for micro-structuring by creating Nano-scale roughness on surfaces. The rougher surface helps coatings stick better, boosting performance and durability in applications that need strong bonding and precise material interaction.

Adjusting plasma parameters such as power, gas composition, and exposure time enables effective cleaning and activation of both plastic substrates and metal layers.

This process tailors the plasma treatment to enhance adhesion and surface properties for diverse material combinations.

Exploring the benefits of plasma cleaning uncovers its effectiveness in enhancing anti-static coating adhesion and overall performance on metalized plastics.

Plasma is instrumental in improving coating adhesion for anti-static coatings on metalized plastics.

Plasma cleaning improves surface particle characteristics for metalized plastics, making them more receptive to anti-static coatings. This process helps ensure strong, uniform, anti-static coatings bonding to metalized surfaces.

Plasma enhances the performance and durability of anti-static coating on metalized plastic surfaces.

Plasma cleaning reconfigures the surface characteristics to ensure that anti-static properties remain effective over prolonged use, even under mechanical stress.

Plasma cleaning is an eco-friendly process requiring no chemical primers or harmful reagents.

The process also does not need extreme heat to occur. Plasma processes can occur at low temperatures and low pressure.

The precision nature of plasma processes also ensures that little or no waste is left behind, which can constitute nuisance in the environment.

Plasma treatment reduces coating defects by enhancing surface cleanliness and adhesion, leading to fewer rejections and rework.

This boosts manufacturing efficiency, cuts waste, reduces costs, and increases productivity while ensuring high-quality, consistent products across industries.

Plasma ensures consistency and scalability in high-volume production by providing uniform surface preparation.

This consistency is crucial for mass manufacturing, minimizing variations and defects, and enabling reliable quality control across large batches.

Understanding the applications of plasma-treated metalized plastics highlights their versatility and enhanced performance across various industries.

Plasma provides reliable anti-static coatings on housings and components for EMI shielding and ESD protection. It is utilized in printing circuit boards and other electronic components.

In the automotive industry, plasma treatment is applied to metalized plastic interior parts to ensure durable coatings.

This process enhances adhesion and surface properties, preventing static buildup and extending the life and performance of components under varying usage conditions.

Plasma treatments enhance anti-static properties in decorative metallized plastics by altering surface energy and creating a conductive layer.

This minimizes static charge buildup, improving safety and performance in household appliances and packaging by reducing dust attraction and electrostatic discharge risks.

Plasma treatments create static-free surfaces on metallized plastic parts by depositing a conductive, anti-static layer.

This minimizes static accumulation, ensuring clean and sterile operations in medical devices by reducing dust.

Examining process optimization for plasma cleaning uncovers methods to boost cleaning efficiency and improve surface treatment results.

Adjusting key parameters is necessary for optimizing plasma cleaning for metalized plastics. Selecting the right gas is appropriate for the success of the process.

Whether you would eventually use oxygen, argon, or nitrogen will depend on the material and coating requirements.

Power and duration must also be regulated to suit business needs. Hence, it is vital to adjust energy levels to avoid damaging delicate plastic substrates.

Finally, chamber conditions must be tweaked to ensure consistent plasma exposure across complex geometries.

Plasma treatment enhances surface wettability by increasing surface energy. This can be assessed using contact angle measurements, where a reduced contact angle indicates improved wettability, which is vital for coatings, adhesives, and printing applications.

Adhesion testing evaluates the strength and uniformity of anti-static coatings by measuring resistance to peeling or shearing forces. This ensures reliable and consistent bonding on treated surfaces for optimal performance.

Automating plasma systems streamlines high-speed manufacturing by ensuring precision, consistency, and efficiency in treating surfaces.

It cuts human mistakes, speeds up production, and improves control, offering consistent, high-quality results for electronics, automotive, and consumer goods.

Avoiding over-treatment during plasma cleaning is crucial to prevent damage to the plastic substrate or metalized layer.

Precise control of exposure time and plasma intensity ensures effective cleaning while maintaining the integrity and performance of the delicate surface layers.

Plasma provides uniform treatment on complex geometries by conforming to varied shapes and thin metal layers.

This provides even coverage and improves surfaces, boosting adhesion and anti-corrosion without damaging delicate features in electronics, car parts, and complex components.

Paying upfront for a plasma cleaning machine does cost a bit. The implementation is also not cheap.

But, a plasma cleaning system will bring many benefits alongside its usage. So, balancing initial equipment investment with long-term benefits in product quality is essential to get a wholistic picture of the business.

Plasma enhances the quality and durability of metalized plastics. It helps to ensure metalized plastics meet industry standards for anti-static performance and durability.

Plasma-treated metallized plastics enhance adhesion, ensuring longer-lasting anti-static properties in sensitive electronic devices.

This treatment strengthens layer bonds, cuts static buildup, and protects against electrostatic discharge, boosting the durability and performance of electronic parts.

Plasma treatment enhances the durability and aesthetic appeal of anti-static coatings on decorative parts by improving adhesion and creating a smooth, uniform surface.

This results in longer-lasting, visually appealing finishes that resist wear and static buildup, which are ideal for consumer and industrial applications.

Plasma cleaning of metallized plastic packaging reduces static buildup, enhancing cleanliness and ease of handling.

This treatment minimizes dust attraction and the risk of contamination, ensuring safer and more efficient packaging processes, particularly in the food, electronics, and pharmaceutical industries.

Plasma-prepared surfaces enable the application of next-generation multi-functional coatings by enhancing surface energy and ensuring excellent adhesion.

This makes it possible to apply advanced self-cleaning, anti-microbial, and more durable coatings, helping industries like electronics, automotive, and aerospace innovate and achieve better performance.

AI is slowly taking its place in several industries, including manufacturing outfits. With AI-driven features, plasma cleaning machines can achieve real-time monitoring and optimization for consistent quality. This will significantly impact the efficiency and durability of metalized plastics.

Plasma technology offers an eco-friendly alternative to chemical-based surface preparation methods by reducing hazardous waste and energy use.

It precisely and efficiently modifies surfaces without harmful chemicals, supporting sustainable manufacturing, electronics, and healthcare practices while maintaining high-quality results.

Tailored plasma processes are emerging as a future trend, addressing specific industrial needs and complex component designs.

Customizing treatments enables industries to prepare surfaces precisely and boost performance, managing complex shapes and materials while driving innovation and efficiency in various applications.

Metalized plastics are helpful in many industries for being lightweight and conductive. Still, they struggle with surface dirt and low energy, making it hard for anti-static coatings to stick well.

These problems can stop anti-static coatings from sticking correctly. Thankfully, plasma treatment is a good solution that offers precise cleaning and surface preparation.

With plasma technology, industries can make metalized plastics work better and more reliably in applications. Visit Fari Plasma today for various cutting-edge plasma cleaning systems.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate