Have you ever wondered how the medical fraternity uses catheters and how they can be improved? Polypropylene (PP) catheters are the flexible hoses that general practitioners use to cure various disorders.

They are ideal for easing pee problems, projecting drugs into the body of the patient, and are beneficial during heart surgery. These catheters can be made better by attaching a special hydrophilic coating.

However, this coating doesn’t stick on it as smoothly. The process of plasma cleaning solves this issue by turning the plastics completely clean and makes it easier to apply the coat.

PP catheters are made of a special plastic that keeps water out. The PP tubes are produced from a synthetic material named polypropylene which is a thermoplastic polymer. These are devices that are manufactured with super-strength technology preventing them from getting fatigue and they are tough enough to endure repetition without becoming thin.

PP catheters have neither toxic nor harmful effects like some of the metals and in fact, the main characteristic of PP is the fact that it is biocompatible. This is great for solving many problems, but what about issues with the coating?

Yes, exactly. The plastic is so rigid that it doesn’t even bind with other materials, which is suitable for safety, but on the other hand, it causes the problem of hydrophilic coating to stick with it.

Chemicals such as oils are used to modify materials to change the landscape. However, these oils will hold on to the catheter and prevent this hydrophilic coating from attaching.

It is like sticking on a panel covered with a layer of oil. This is just ridiculous; it can’t work!

Plasma cleaning is super energized gas used in the cleaning process for tough and hard substances which are quite difficult to clean normally!

Apart from being super-cool, Plasma cleaning does the following:

Here are the advantages of plasma cleaning for PP catheters.

Plasma cleaning is a technique that significantly improves the adhesion of the hydrophilic coating to the catheter. As an alternative, you could picture using an incredibly stronger glue rather than the regular one.

Which interprets that the coating will never be easily removed, a thing that is mandatory if we are to run the catheter.

Through this new and better coating procedure, the catheter functions as it should, in all the times that it is in use. This is particularly good whether you have or someone else needs a catheter because the results will be definitely positive when the device performs as expected, and you will relax more.

You will be glad to hear that plasma cleaning is a process that is friendly to the environment. No toxic chemicals are used that can bring the coating to adhere to the device. That means it’s not a dangerous process for nature and we can all accept it.

Plasma cleaning enables catheters to be produced on a large scale to ensure their continued availability to those who need them.

Remember the catheters for Urologic diseases? They can be very easy & comfortable, so even if you have to use one for a long time, it will still be very comfortable.

For heart issues, plasma cleaning is sufficient as it ensures the coating is fixed perfectly. This is very beneficial as no clumps will be formed, and the blood can travel freely.

When doctors need to give you medicine through a tube, plasma cleaning ensures the coating is just perfect so that medicine automatically enters.

So, you get the required treatment to control your health.

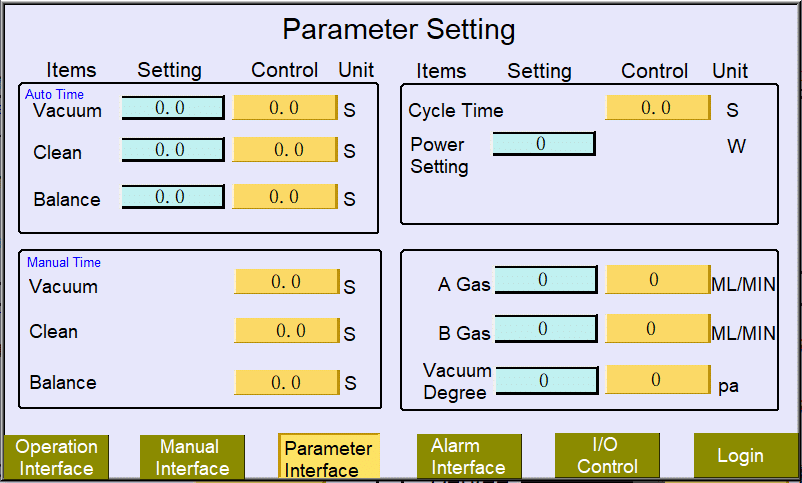

On the path of repairing PP catheters with hydrophilic coats, plasma cleaning has played a crucial role. To ensure the most effective cleaning process, you need to pay attention to several key parameters. Well, let’s take a closer look at these necessary factors.

The kind of gas you select for plasma cleaning is very crucial. More often, two gases are used in this process:

Each gas has its own features and effects on the cleaning process. Your choice will be based on the specific needs of your PP catheters and the result you want to get from the cleaning process.

The setting way of the power during the plasma cleaning is another main factor that should be controlled properly. To balance between a safe power level and a cleaning process that works, you can adjust the plasma power slightly.

The application of a high plasma power level can both be a risk for the catheter and a cause for changes in its properties. On the one hand, it may damage the material of the catheter and on the other hand, it may change its structural stability and because of this, it may break off.

The right equilibrium between being able to produce the output and the risk of the device being injured should be found.

Time is another highly critical factor when it comes to the plasma cleaning process. Determine how long the catheters should be cleaned based on their special characteristics.

The idea here is just to make it neat and clean. A too short cycle will result in poor cleaning and improper use of the resources, while a very long one could lead to the changing of the catheter’s properties and resource wastage.

This will be the best approach to preparing your PP catheters for hydrophilic coatings. This procedure will not only help you to upgrade the functions and utilities of your devices but also prolong their working lifetime.

Following the plasma cleaning process, we must run the post-treatment checks to determine its success. They are:

You can install plasma cleaning machines in the factory line to increase catheter production. It could be like a special car wash for catheters!

You mustn’t ruin the catheter while you are cleaning it. Excessive heat and roughness may damage the catheter.

Catheters are very diverse in shape, so the plasma cleaning should take every part into account and not be skipped.

Plasma cleaning machines might require a large budget. Companies should evaluate the cost against the benefits of producing better-quality catheters.

There is a lot of definite data about the production of medical appliances. The catheters cleaned with plasma need to be made in line with these regulations so they do not expose you to hazards.

Of the many competing products, the doctors inspected the catheters and found that the plasma cleaned had the best results of all the time they were used!

The great thing is that many plants that produce millions of catheters have recently switched over to plasma cleaning. They preferred this method, out of many others, even after the operation of making so many products, was still working correctly.

The larger factories found that they were producing even more resistant catheters after implementing plasma cleaning and having fewer problems, including those of managers, workers, and all employees. It’s a win for everyone!

Scientists are developing more and more interesting coatings. Thanks to plasma cleaning, we expect new types of coatings that are non-invasive, antimicrobial, and even better than the current ones!

Maybe we will have the AI to monitor the plasma cleaning process and make it the best, all by itself!

Businesses are trying to make medical products in such a way that they are not hazardous to our planet. So, they employ plasma cleaning that aligns with such green ways of thinking.

Isn’t it amazing that we know the ways and means to create catheters that may be more beneficial in so many ways than the ones that exist now? Plasma cleaning is akin to the superhero of medicine technology.

At Fari plasma, we work wonders in making catheters more comfortable, safe, and efficient, helping your health and benefiting the whole planet.

Technology is in its race; thus, it is unknown where its lead will be. Nevertheless, the world of medical devices is so fascinating to the occupants!

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate