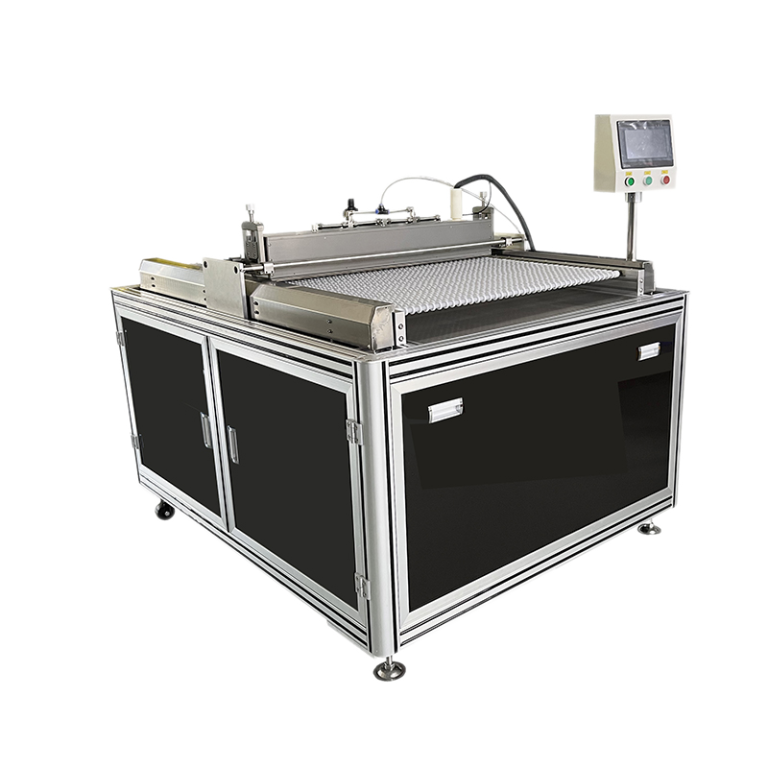

The PM-G16D is a nitrogen wide-width plasma surface treatment system offering high-efficiency cleaning and activation for diverse substrates across electronics, solar, automotive, packaging and biomedical industries.

| Power supply | AC 220V, 50/60 Hz |

| Main power rating | 3800 W |

| Main unit size | 550 mm (L) × 350 mm (W) × 472 mm (H) |

| Main unit weight | 32 kg |

| Generator power consumption | 1500 W |

| Generator frequency | 18–25 kHz |

| Nozzle treatment width | 400 mm (customizable) |

| Nozzle treatment height | 3–5 mm (recommended 3 mm) |

| Nozzle size | 508 mm (L) × 116 mm (W) × 133 mm (H) |

| Nozzle weight | 13 kg |

| Cable length | 3 m (customizable) |

| Process gas (usable) | Nitrogen (recommend N2 ≥ 99.9%) |

| Gas consumption | 110 L/min |

| Gas pressure | 4–5 kg/cm² |

| Conveyor line speed | 0.5–4 m/min |

| Control system | IO control |

| Alarm & protections | Pressure, power, temperature detection; overload protection; abnormal plasma/flame alarm output |

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate