The global polymer-based footwear market is expected to reach USD 595.7 Billion by 2030. Many shoemakers are utilizing materials such as TPU, EVA, and PVC due to their strength, elasticity, and low production costs.

However, these polymer surfaces don’t like water too much (we call them hydrophobic), and they can get pretty dirty during manufacturing.

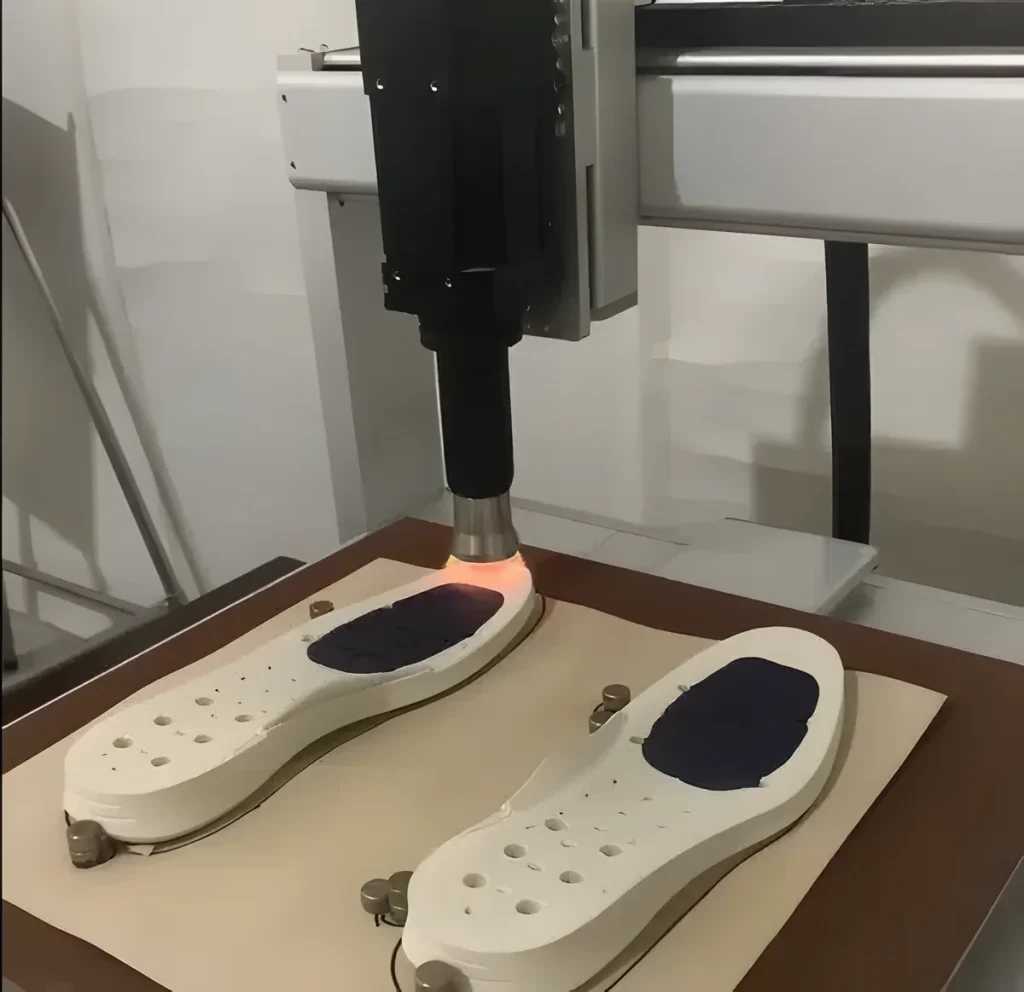

Plasma technology not only helps the materials to adhere better but also cleans them up simultaneously. The best part is you do not even need to use harmful chemicals!

Let’s dissect the polymer shoe game.

TPU (Thermoplastic Polyurethane)

It is the hero material of the shoe. It is used in the part of your shoe that needs to be strong and can last long without getting worn or torn, such as midsoles and outsoles. It’s like you put the suit on the shoes, which makes them flexible and armor-like as well.

EVA (Ethylene Vinyl Acetate)

Remember the light-as-a-feather shoes? It’s because of EVA! It is really lightweight and capable of handling all the service impacts. It mounts the soft part inside your soles.

PVC (Polyvinyl Chloride)

It is part of a group that has the imagination gene. PVC is regularly used to prettify shoes or to protect them, treating them as if they are elegant but real at the same time.

These materials are just excellent, but they have some issues too:

Low Surface Energy

Can you write while a surface is moving away from your pen? That’s a little of what happens when you glue those polymers. They have a weird affection for adhesives but still won’t bond with them.

Contaminants

These surfaces are a nightmare during the shoe-making process. Oils, dust, and many other tiny troublemakers can be why glues do not function properly.

Plasma cleaning is like brushing your shoes clean and, at the same time, charging the materials with electricity so that they become more attached with glues.

Let’s walk through this binding process:

Surface Cleaning

It acts like a tiny vacuum cleaner to begin with, collecting all the dirt, oils, and other stuff from the surface. That way, the shoe material remains crystal clear!

Surface Activation

After that, it is likely to give the surface a jolt. It makes the surface more energetic, so it is then ready to bond with adhesives.

Micro-Etching

Finally, it makes the surface a little rougher—not enough to notice, but enough to provide the glue with something to grab.

One of the great prizes is that your shoes now stick like never before. You do not have to worry about parts falling out, even if it happens after a couple of wears.

Now, your shoes can bear what comes their way – rain, mud, or challenging marathon running.

This treatment does not burn the earth up by chemicals that decay it. So, it is suitable for everyone and ec-friendly for our Earth.

Not a single polymer would resist its magic. It acts as a mediator for them all. Plasma treatment is a technology that has brought a common language between shoe materials.

Consequently, the initiative will be helpful for large shoe companies. It enables the equal treatment of thousands of shoes, thus making them the best.

Midsole separates the upper part and the bottom tread. It especially gives extra padding and cushioning. The bottom portion of the shoe directly in contact with the ground is called the outsole. It is the one that provides grip and resistance.

Why is Bonding Important?

These two positive ions adhere to each other thanks to the bonding of these two parts. Here is a bit of an explanation of why bonding is so vital:

How Does the Bonding Process Work?

The bonding process usually includes the following procedures:

More complex methods, however, might require the use of heat or compression to solidify the bond.

With plasma treatment on those lovely logos and small intricate parts, they will become permanent. No more defenseless logos. It will not be just a dream—your shoe will become Eden and never fall apart in the process of your playful action.

Using plasma treatment for those special coatings that need extra stickiness means that shoes not only become more durable but also you do not have to worry about your feet getting wet or slippery.

Even in the old models of shoes, the techniques of plasma treatment have given them a new life. Plasma treatment makes the repairs stronger; thus, it helps the shoes to stay around longer.

Following are the important parameters for process optimization.

Gas Selection

The gas used in plasma treatments during the process of producing sporting shoes is a key component. The gases are diverse and provide the following benefits:

Power and Exposure Time

It is a harmonious interrelation of these two variables that makes plasma treatments efficient:

Chamber Conditions

Now imagine having created the perfect environment for plasma to act just right on all the parts of the shoe.

Lower pressure settings produce the most uniform plasma distribution. The temperature monitoring and controlling make sure that materials will not be degraded. The lower the humidity, the less influence the plasma process is affected by it.

After the plasma treatment, this is the keystone moment! They have to fasten the glue as quickly as possible to achieve the maximum surface coverage without it being too adhesive.

If you overheat frozen foods, do you expect them to retain their original taste? Polymer materials are similar because they don’t want to be treated too much differently in terms of their look and feel.

Inserting this new technology into an existing shoe factory can be difficult. It’s like a dance that keeps getting more challenging by introducing more complicated moves.

Although the cost of setting up plasma treatment may be high at first, the long-term benefits of improved shoe quality and less waste make it worth the investment.

Shoe companies want to ensure that their plasma-treated shoes adhere to all safety regulations.

Just think. Would it not seem fantastic to witness sportsmen who get to the finish line without broken shoes, no matter how demanding the distance? The secret of plasma treatment was unveiled when TPU midsoles remained undamaged even with intense sports.

Fashion is the field where the trend is the most discussed. Fast fashion and decorative items are carrying out a plasma treatment.

Manufacturers have found that using plasma instead of chemical primers on shoes is a stepping stone to making the shoes more eco-friendly once production is rolled out. It is the equivalent of giving one another a high five.

We are truly stepping into a future with super-strong, super-flexible adhesives that are even more effective on plasma-treated surfaces.

Think of intelligent robots who know how to optimize treatments according to the detail of a shoe and its material for the best outcome regarding stickiness. We are set to get there!

Pico plasma technology is only the beginning. We can expect a future in which making shoes will not be so hard on our planet.

Imagine shoes that are not just for this decade but for the 22nd century! Then, we can see new-fangled units that are not obtainable now; that is the wonder of plasma treatment.

What’s rocking the shoe world is the miraculous change through plasma technique. It has enabled the shoes to be more hardwearing, thus, long-lasting and earth-friendlier.

Fari Plasma has advanced plasma technology to make this revolution possible on a large scale industrial level.

So when you put on your sneakers and feel the robotic leg strength, think of the cutting-edge science that is making it happen. The future of shoe production becomes so apparent – it is brighter and glue-based like nothing else!

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate