Plasma cleaning has become an indispensable technology across numerous industries, from semiconductors to advanced materials processing. At Fari Plasma, we understand that selecting the correct plasma gas is crucial for achieving optimal results.

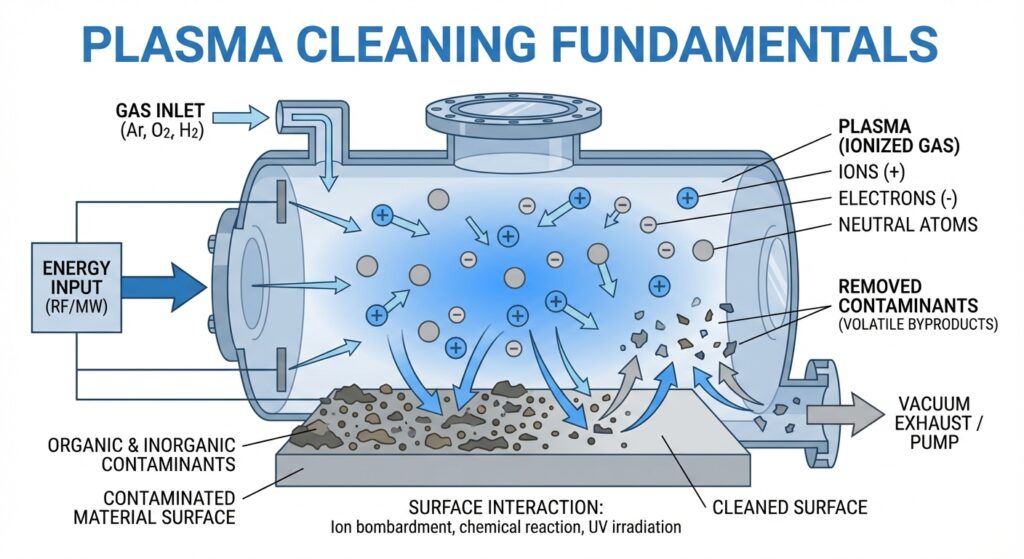

Plasma is ionized gas containing electrons, ions, and neutral atoms. When energy is applied to gas in a vacuum, it ionizes and creates plasma that removes surface contaminants.

The cleaning mechanism involves several processes:

The choice between argon and oxygen plasma dramatically affects which of these mechanisms dominate and how effectively they address your specific contamination challenges.

What is Argon Plasma?

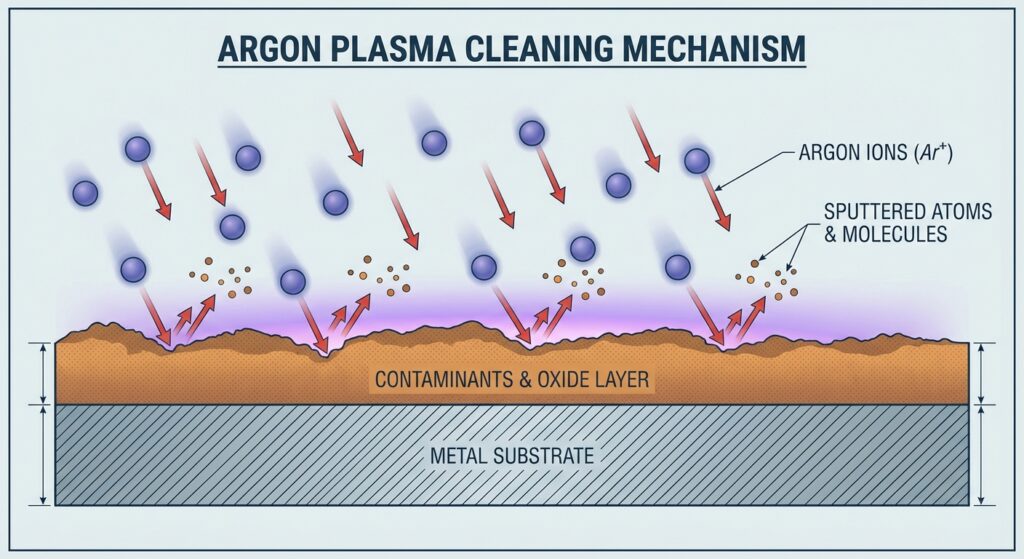

Argon is a noble gas—chemically inert and non-reactive. When ionized into plasma, argon primarily works through physical mechanisms rather than chemical reactions. This fundamental characteristic makes argon plasma particularly valuable for specific applications.

Key Characteristics of Argon Plasma

Argon plasma operates almost exclusively through physical sputtering. The energetic argon ions strike the surface with considerable force, mechanically dislodging contaminants, oxides, and other unwanted materials. Because argon is inert, it doesn't form new chemical compounds with the substrate material.

Advantages of Argon Plasma Cleaning:

Limitations of Argon Plasma

Ideal Applications for Argon Plasma:

What is Oxygen Plasma?

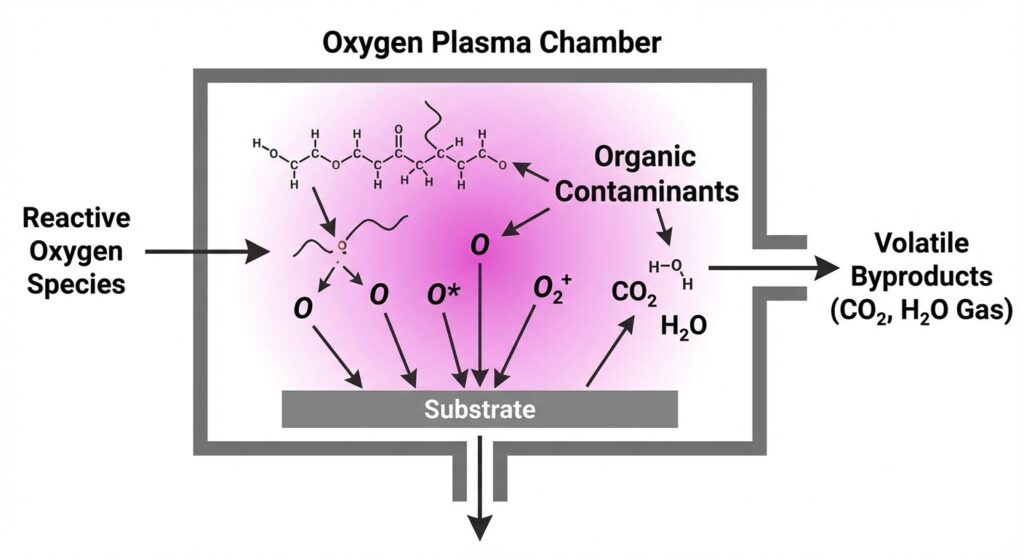

Oxygen plasma is created by ionizing oxygen gas, which produces a highly reactive environment. Unlike argon, oxygen atoms and ions are chemically active and readily form compounds with other materials. This reactivity is the defining characteristic that distinguishes oxygen plasma cleaning.

Key Characteristics of Oxygen Plasma

Oxygen plasma cleaning relies primarily on chemical reactions. The reactive oxygen species—including atomic oxygen, ozone, and oxygen ions—chemically attack and break down organic molecules, polymers, and contaminants. This is why oxygen plasma is particularly effective at removing organic residues.

Advantages of Oxygen Plasma Cleaning:

Limitations of Oxygen Plasma

Ideal Applications for Oxygen Plasma:

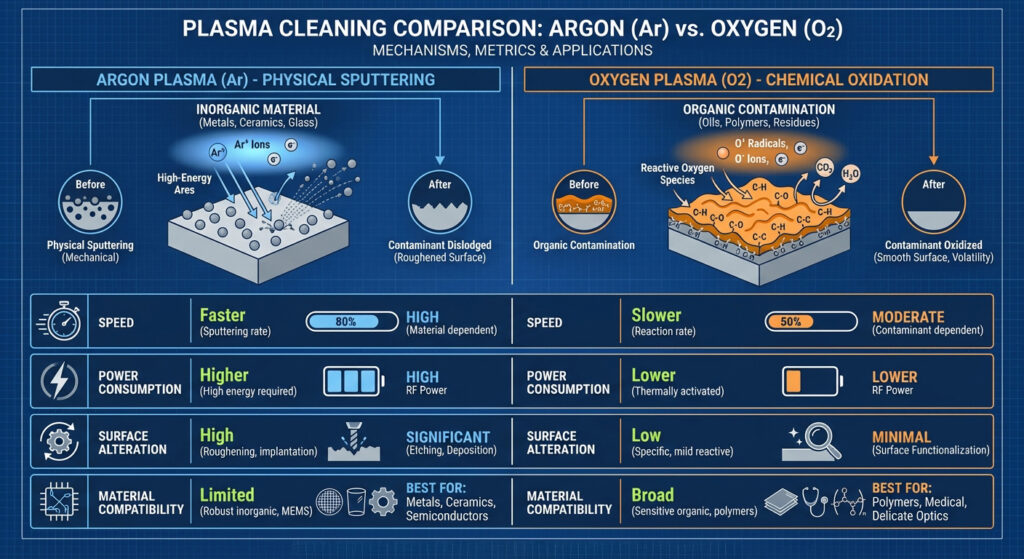

| Factor | Argon Plasma | Oxygen Plasma |

|---|---|---|

| Mechanism | Physical sputtering | Chemical reaction |

| Best for | Inorganic, oxides, metals | Organic contaminants |

| Surface alteration | Minimal chemical change | Creates oxidation |

| Speed | Slower | Faster |

| Power consumption | Higher | Lower |

| Material compatibility | Universal | Limited (no reactive metals) |

| Surface damage risk | Higher (physical) | Lower |

| Cost per cycle | Higher | Lower |

| Oxide removal | Excellent | Poor |

| Organic removal | Poor | Excellent |

Many modern applications benefit from combining argon and oxygen plasma in sequential treatments. For example:

This dual-approach maximizes cleaning effectiveness while maintaining optimal surface properties for your specific requirements.

The choice between argon and oxygen plasma cleaning isn't about finding a universally "better" option—it's about matching the gas to your specific application requirements. Argon excels at inorganic cleaning and preserving surface chemistry, while oxygen plasma rapidly removes organic contaminants and activates surfaces.

At Fari Plasma, our expertise spans both technologies. We recommend evaluating your specific contamination challenges, material compatibility requirements, and cost considerations. Many manufacturers find that the optimal solution involves understanding both gases thoroughly and selecting—or combining—them strategically.

Whether you're processing semiconductors, medical devices, or advanced materials, the right plasma cleaning technology can dramatically improve your product quality and manufacturing efficiency. Contact our team to discuss your specific plasma cleaning challenges and discover how Fari Plasma equipment can optimize your processes.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate