Atmospheric plasma treatment has emerged as a revolutionary technology in modern manufacturing and materials processing. Unlike traditional surface treatment methods that require complex vacuum systems or harsh chemical processes, atmospheric plasma treatment operates at normal air pressure.

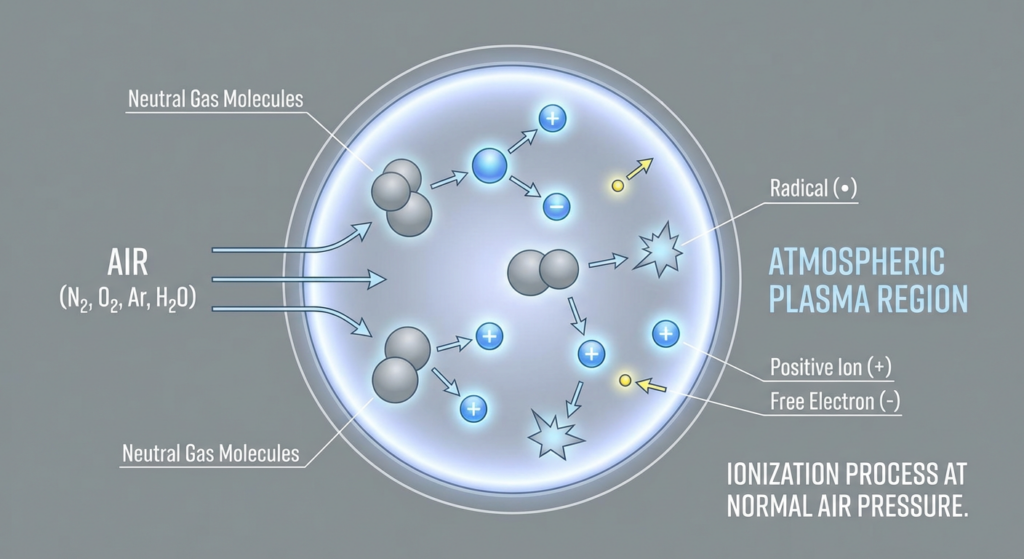

Plasma is often referred to as the "fourth state of matter," existing alongside solids, liquids, and gases. When ordinary gas is ionized—meaning electrons are stripped away from atoms—it becomes plasma, a collection of ions, electrons, and neutral particles. Atmospheric plasma specifically refers to plasma generated and maintained at normal atmospheric pressure, rather than in a vacuum chamber.

In atmospheric plasma treatment systems, energy is applied to ambient air (or another working gas) to create this ionized state. This energy source ionizes gas molecules, creating highly reactive species including ions, electrons, excited atoms, and free radicals. These reactive components are what make atmospheric plasma such a powerful treatment tool.

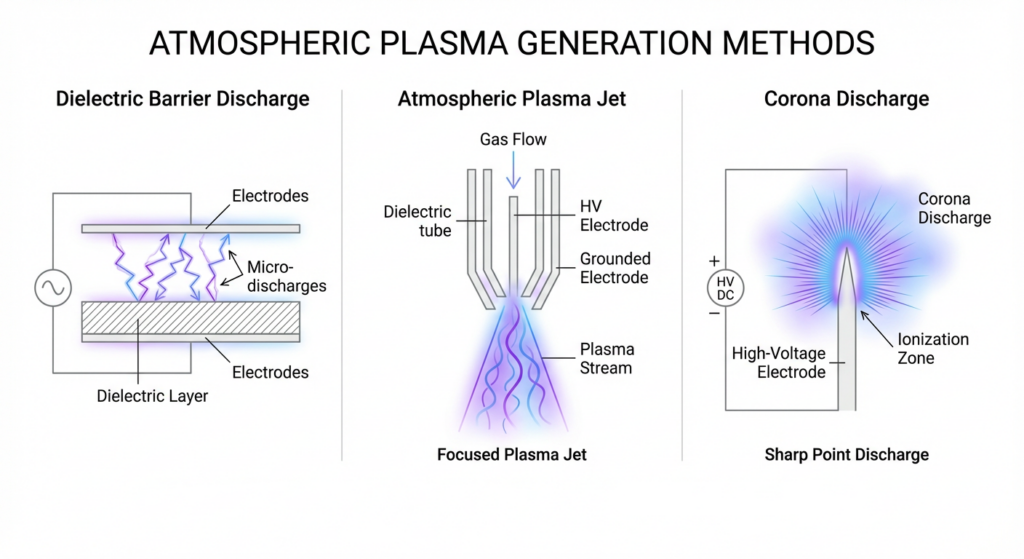

Atmospheric plasma treatment systems typically generate plasma through one of several methods:

Dielectric Barrier Discharge (DBD): This is the most common approach for atmospheric plasma generation. DBD systems use an electric field between two electrodes separated by a dielectric material. When high voltage is applied, the gas breaks down into plasma at specific locations, creating numerous micro-discharges. This method is particularly effective because it prevents the formation of a single large arc, instead creating a diffuse, uniform plasma.

Atmospheric Pressure Plasma Jets (APPJ): These systems generate plasma in a confined region and direct it as a jet toward the target surface. This approach allows for precise treatment of specific areas and is ideal for sensitive or complex geometries.

Corona Discharge: This method uses a high-voltage electrode to ionize air, creating a corona effect. The resulting plasma can be applied to surfaces for various treatment purposes.

Once plasma is generated, its reactive components interact with the target material's surface through several key mechanisms:

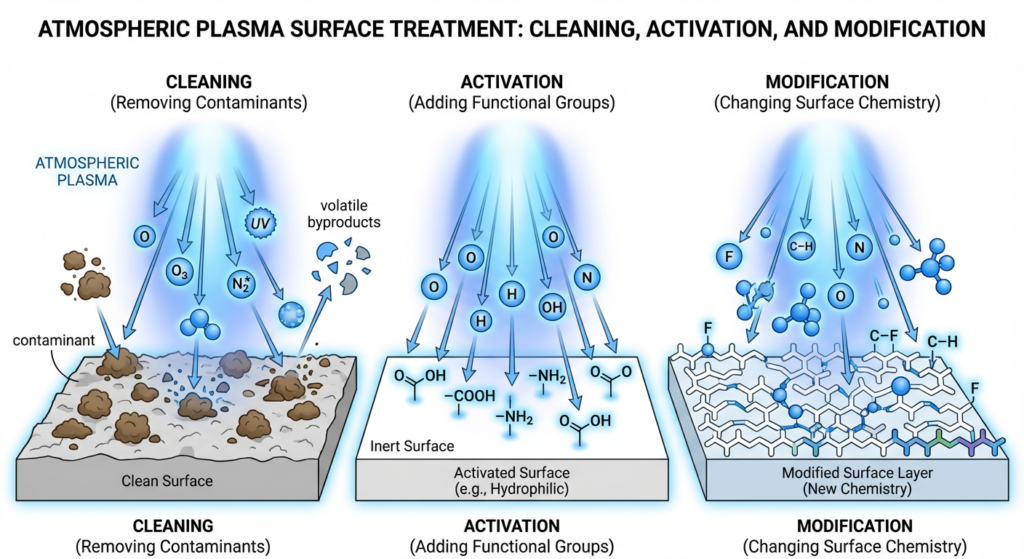

Surface Cleaning: Energetic ions and free radicals remove organic contaminants, oxides, and other surface impurities. This is far more effective than mechanical scrubbing and doesn't require liquid chemicals.

Surface Activation: Plasma treatment creates reactive functional groups on the material surface. For polymers, this increases surface energy and wettability, improving adhesion for subsequent bonding, coating, or printing applications.

Surface Modification: The plasma modifies the chemical composition of the top molecular layers. This can improve properties like hydrophilicity (water attraction) or create specific surface characteristics needed for particular applications.

Sterilization: In applications requiring sanitization, the reactive species in plasma effectively eliminate bacteria, viruses, and other microorganisms, making it valuable for medical and food processing applications.

Unlike many traditional surface treatment methods, atmospheric plasma treatment:

Treatment times are typically measured in seconds or fractions of a second, enabling high-speed inline processing. This makes atmospheric plasma particularly attractive for high-volume manufacturing environments where productivity directly impacts profitability.

The effectiveness of atmospheric plasma treatment stems from the synergistic action of multiple reactive species. These include:

This multi-faceted attack on surface contamination and surface properties is why plasma treatment often outperforms single-mechanism treatment approaches.

Atmospheric plasma treatment represents a paradigm shift in surface processing technology. By harnessing the unique properties of ionized gas at normal pressure, manufacturers can achieve superior surface preparation, activation, and modification while reducing environmental impact and operational costs. As industries worldwide face increasing pressure to improve product quality while maintaining sustainability, atmospheric plasma treatment has proven to be a transformative technology that meets both demands.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate