In today's advanced manufacturing environment, precision is paramount. Whether in semiconductor fabrication, medical device production, or aerospace engineering, even microscopic contaminants can compromise product quality, reliability, and performance. This is where plasma cleaning technology comes in.

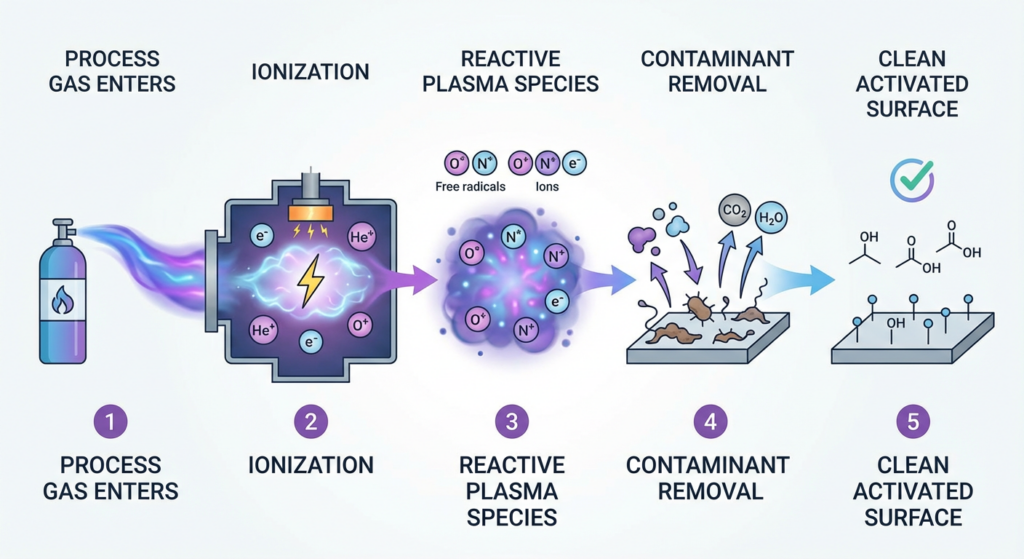

Plasma cleaning operates through several interconnected mechanisms that work together to remove contaminants at a molecular level:

When atmospheric air, oxygen, nitrogen, or other gases pass through an electrical discharge field, the gas molecules become ionized. This creates highly reactive species including ions, electrons, excited atoms, and free radicals. These reactive particles possess significantly higher energy levels than their non-ionized counterparts, making them exceptionally effective at breaking chemical bonds.

Once activated, plasma constituents engage in chemical reactions with surface contaminants. For example, in oxygen plasma, atomic oxygen reacts with organic compounds—oils, resins, photoresist, and polymer residues—converting them into volatile byproducts like carbon dioxide and water vapor. These gaseous products are then evacuated from the treatment chamber, leaving the underlying surface pristine.

Beyond chemical reactions, plasma cleaning also involves physical mechanisms. Energetic ions bombard the surface with kinetic energy, physically dislodging contaminant particles and loosened molecular layers. This sputtering action is particularly effective for removing stubborn residues that resist chemical attack alone.

One of plasma's most valuable characteristics is its ability to activate surfaces. The energetic particles don't just remove contamination—they also modify the surface chemistry itself. This creates a more reactive, higher-energy surface that enhances adhesion properties. Surfaces treated with plasma often show dramatically improved bonding characteristics, making it invaluable for subsequent coating, adhesive, or lamination processes.

Different applications require different plasma technologies. Fari Plasma offers various solutions tailored to specific industrial needs:

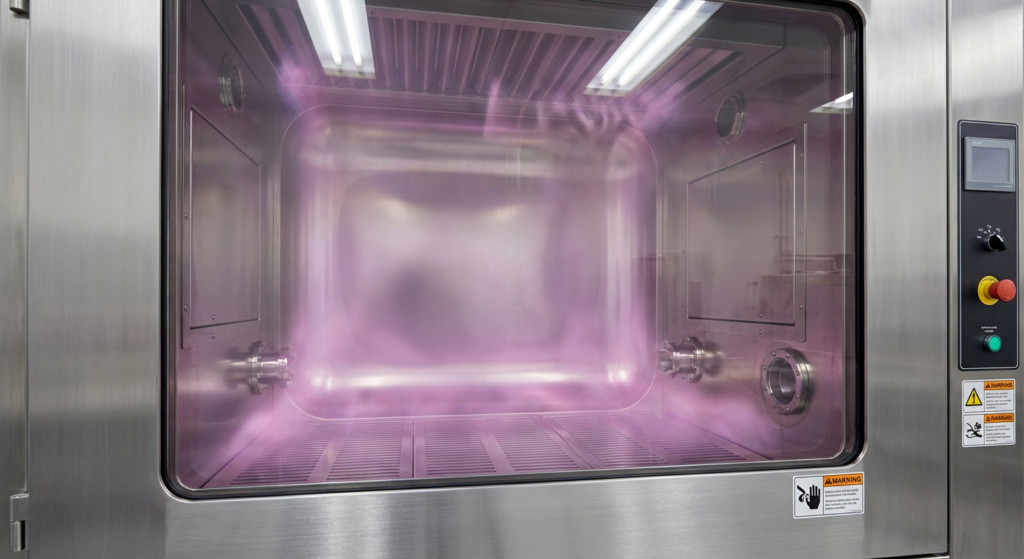

Our plasma cleaners provide high-efficiency surface cleaning inside a controlled low-pressure chamber. Designed for precision industries, they remove organic contaminants at the molecular level, ensuring optimal adhesion, coating quality, and bonding performance. Ideal for laboratories, R&D, and small to medium production environments.

These systems deliver powerful surface activation and modification for plastics, metals, ceramics, and composites. Built for inline or standalone industrial use, they enhance wettability, printability, bonding strength, and coating performance—perfect for automotive, medical, packaging, and electronics manufacturing.

Engineered for the demanding semiconductor sector, our systems support processes such as ashing, descum, micro-cleaning, and wafer surface activation. With nanometer-level precision, uniform plasma distribution, and contamination-free operation, they meet the strict requirements of wafers, MEMS, chips, and optical components.

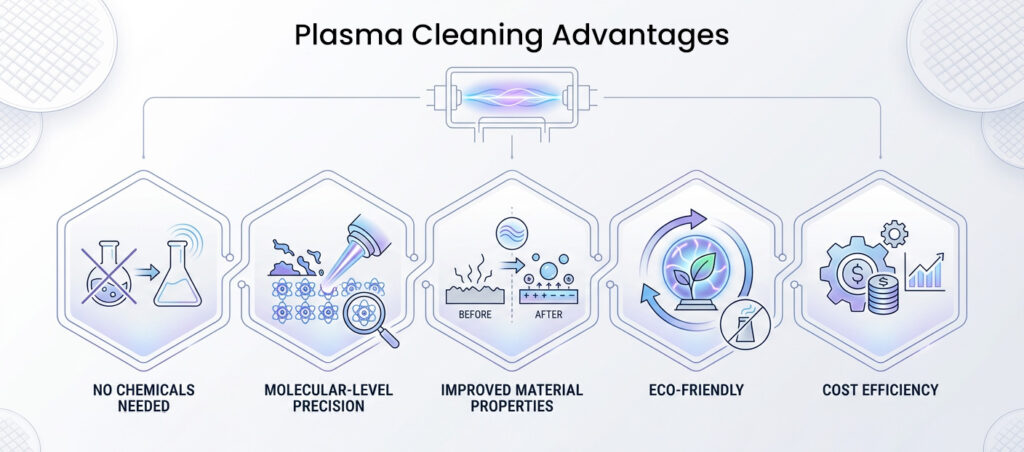

Traditional cleaning methods often rely on solvents and chemical baths—approaches that introduce environmental concerns, worker safety issues, and waste disposal challenges. Plasma cleaning achieves results without hazardous chemicals, producing only harmless gaseous byproducts.

Plasma cleaning removes contamination at the atomic and molecular level, achieving cleanliness levels impossible with mechanical or chemical methods alone. This is particularly critical in industries like semiconductors and pharmaceuticals.

Beyond contamination removal, plasma treatment can modify surface properties—increasing wettability, enhancing biocompatibility, improving printability, and boosting adhesion strength. These property enhancements often translate directly to improved product performance.

Unlike traditional cleaning processes generating chemical waste, plasma cleaning produces only water vapor and carbon dioxide—environmentally benign byproducts. This makes it an eco-friendly choice aligned with modern sustainability goals.

While initial equipment investment may be higher than traditional systems, the operational savings are substantial. Elimination of chemical consumption, reduced water usage, decreased waste disposal costs, and improved product yields combine to create favorable long-term economics.

Plasma parameters can be precisely controlled and monitored, ensuring consistent results from cycle to cycle. This repeatability is crucial for quality assurance and regulatory compliance in regulated industries.

Plasma cleaning has become essential in numerous sectors:

Plasma cleaning represents a paradigm shift in surface treatment technology. By harnessing the power of ionized gases, manufacturers can achieve cleanliness and surface properties that traditional methods simply cannot match. As industries continue pushing toward higher precision, stricter quality standards, and greater environmental responsibility, plasma cleaning technology becomes increasingly essential.

At Fari Plasma, we're committed to advancing this technology and helping our clients unlock its full potential. Whether you need atmospheric plasma cleaning for high-speed production, specialized semiconductor equipment for advanced manufacturing, or customized plasma treatment systems for unique applications, our expertise and equipment deliver results that exceed expectations.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate