Plasma surface activation has become an indispensable technology across numerous industries, from semiconductor manufacturing to medical device production. At Fari Plasma, we specialize in delivering cutting-edge plasma treatment systems that harness this powerful technology to enhance material properties.

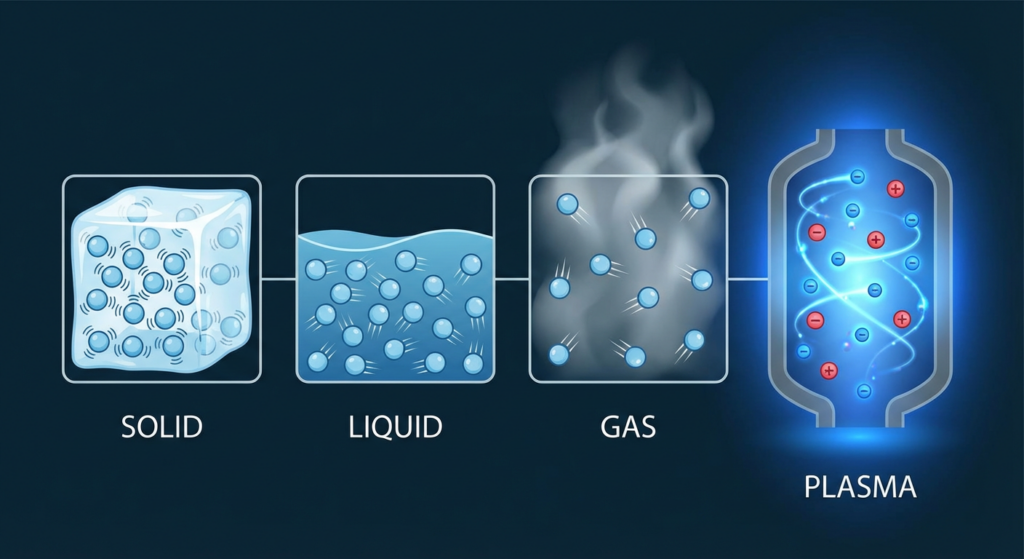

Before diving into surface activation, it's important to understand what plasma is. Plasma is often referred to as the "fourth state of matter," alongside solids, liquids, and gases. It's created when energy is applied to a gas, causing some of its electrons to separate from their atoms, creating a mixture of ions, electrons, and neutral particles.

In industrial applications, plasma is typically generated at room temperature and atmospheric pressure (or in controlled environments) using electrical energy. This is fundamentally different from natural plasma found in stars or lightning, making it safe and practical for manufacturing environments.

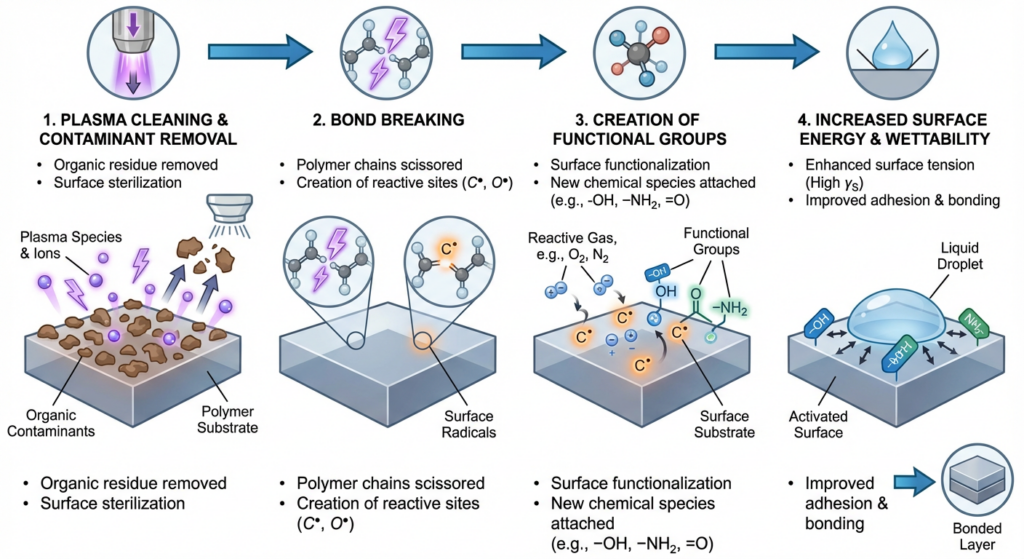

Plasma surface activation is a process where plasma energy is used to modify the chemical and physical properties of a material's surface without affecting its bulk properties. This transformation occurs at the molecular level, creating a more reactive and adhesive surface in a matter of seconds to minutes.

When a surface is exposed to plasma, several simultaneous processes occur:

The result is a surface that's chemically activated and ready for bonding, coating, or adhesive application.

Plasma works through energetic particles—ions, electrons, and excited neutral atoms—that collide with the material surface. These collisions transfer energy that breaks existing chemical bonds and creates new reactive sites. The process is highly efficient because it targets only the surface layer (typically the first 10-100 nanometers), leaving the material's structural integrity unchanged.

Consider a typical surface modification scenario: A polymer or metal surface may initially be covered with a layer of oxidized material or organic contamination. When exposed to plasma:

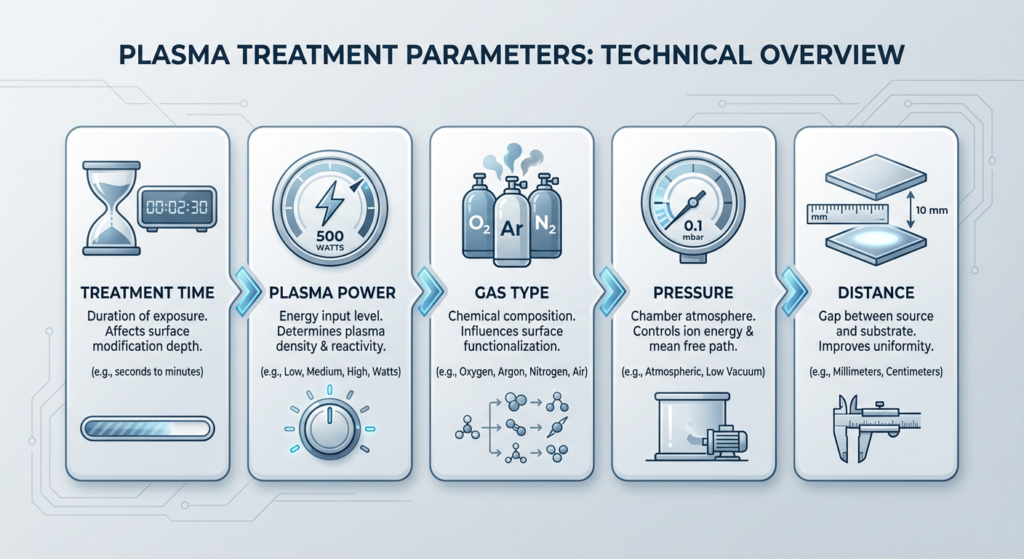

The effectiveness of plasma surface activation depends on several controllable factors:

| Parameter | Effect |

|---|---|

| Treatment Time | Longer exposure increases activation level; diminishing returns beyond optimal time |

| Plasma Power | Higher power increases activation rate; must be optimized to prevent surface damage |

| Gas Type | Different gases (oxygen, nitrogen, argon) produce different chemical functionalities |

| Pressure | Affects plasma density and particle energy |

| Distance from Source | Influences intensity of plasma treatment |

One of the most critical applications is improving adhesion between dissimilar materials. In aerospace and automotive industries, plasma activation enables superior bonding of composites, metals, and polymers—essential for structural integrity.

For example, when bonding carbon fiber composites to aluminum frames, plasma pre-treatment can increase adhesive strength by 200-300%, ensuring reliability in demanding applications.

In semiconductor production, plasma surface activation is crucial for:

Medical devices require exceptional cleanliness and biocompatibility. Plasma activation removes all contaminants from polymer and metal surfaces, creating ideal conditions for sterile assembly and coating with bioactive materials.

In electronics packaging, plasma treatment ensures reliable interconnections and prevents delamination—critical for product longevity and safety.

Environmental Friendliness: Unlike chemical surface treatments, plasma processes generate no hazardous waste and produce no toxic byproducts. The process uses only inert or easily recyclable gases and electrical energy.

Speed and Efficiency: Surface activation occurs in seconds to minutes, dramatically improving manufacturing throughput compared to chemical processes that may require hours of soaking or rinsing.

Precision and Control: Modern plasma systems offer precise control over treatment parameters, enabling consistent, repeatable results across every part.

No Material Damage: Because plasma acts only on the surface, the bulk properties and dimensions of materials remain unchanged, unlike some chemical or mechanical processes.

Versatility: Plasma activation works on nearly all materials—metals, polymers, ceramics, composites, and combinations thereof.

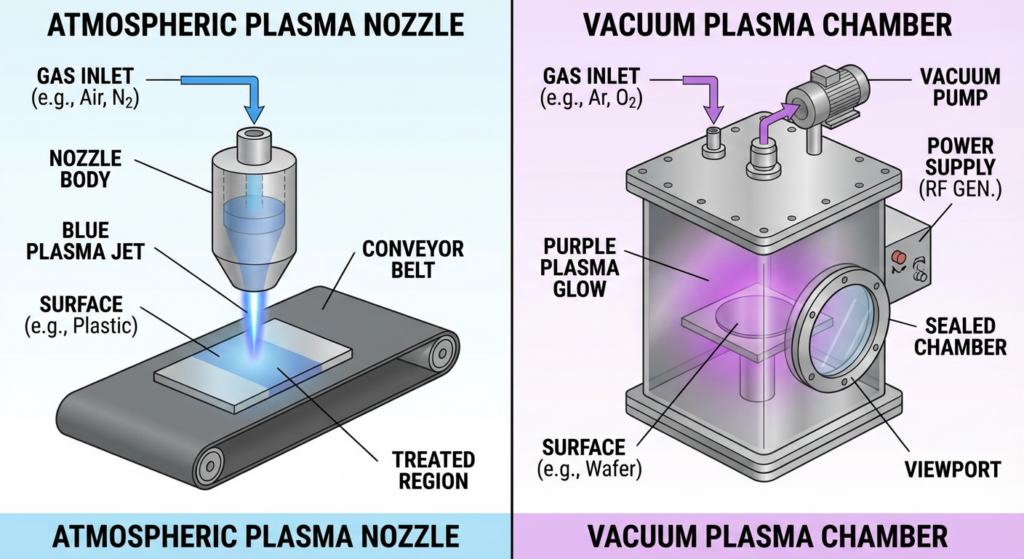

At Fari Plasma, we offer both atmospheric and vacuum-based plasma systems, each with distinct advantages:

Atmospheric Plasma Cleaner: Operates at normal air pressure, eliminating the need for expensive vacuum equipment. Ideal for inline production processes, these systems offer continuous treatment capabilities and lower operational costs.

Vacuum Plasma Systems: Operate in controlled pressure environments, offering superior process control and ideal for applications requiring extreme cleanliness or specific gas mixtures for specialized surface chemistries.

Plasma surface activation represents a remarkable convergence of physics, chemistry, and engineering, enabling material transformations that were previously impossible or impractical. As industries increasingly demand stronger bonds, faster production times, and environmentally sustainable processes, plasma technology has become essential.

At Fari Plasma, we're committed to advancing this technology through innovative atmospheric plasma cleaners, plasma treatment systems, and semiconductor plasma equipment that deliver consistent, reliable results. Whether you're in aerospace, electronics, medical devices, or advanced manufacturing, plasma surface activation can revolutionize your production capabilities and product quality.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate