GD-30 Plasma Cleaning Machine consists of the plasma cleaner host and a vacuum pump. The vacuum chamber size is 350(L)*320(W)*320(H) mm, and the equipment size is 870(L)*740(W)*1540(H) mm. What’s more, we can customize the layer, cavity size and the power frequency with customers. With PLC and touch screen control, it’s very convenient. It can be used for large-scale continuous production and various products.

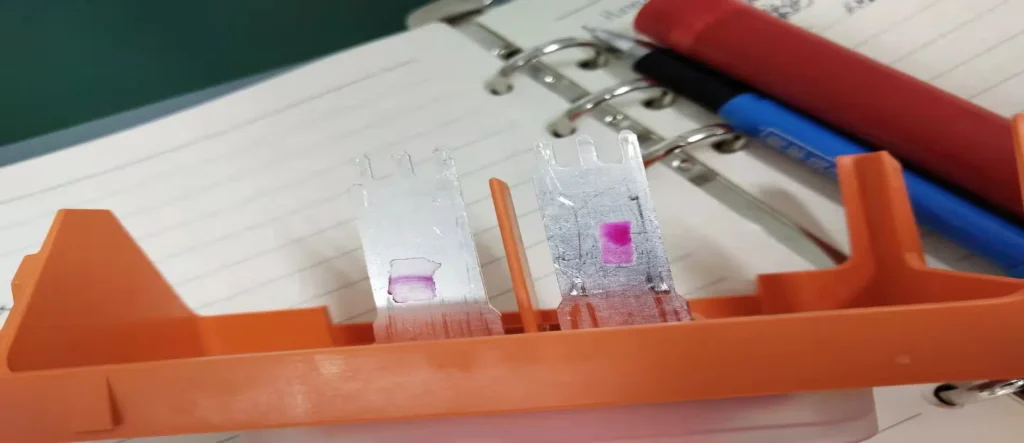

The connector is main clean the lower part where the metal is not leaking. Obviously, using the traditional cleaning way cannot meet the next step requirements. The connector is filled with glue after the copper is silver plated will produce many bobbles, which can lead to the phenomenon of weak bonding.

After vacuum plasma cleaning machine treated, the connector can bonding with the glue have a better bonding effect. In other words, the dyne value can reach 60 dyne. This technique greatly improves the hydrophilicity of metal surfaces and the surface tension.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate