Bottle caps are critical for the beverage industry and play a role in boosting product safety and maintaining quality, in addition to enhancing visual impact and appeal. These caps serve as an extension of the brand’s identity and preserve the product during sale and distribution.

Bottle caps are small but significant components that ensure the safety and preservation of the product while acting as a medium for critical branding elements such as logos, promotional messages, and unique designs. The designs and printed information on the caps must be vibrant, sharp, and resistant to wear.

Achieving this level of quality requires overcoming the inherent challenges posed by the materials and the complexities of production processes. The functionality and aesthetic appeal of bottle caps must align seamlessly with the demands of manufacturers and consumers, making high-quality printing a key factor in successful product development.

Below we will review the common materials used in bottle cap manufacturing, as well as the inherent challenges faced during usage.

Bottle caps are made from thermoplastics, with polypropylene (PP) and polyethylene (PE) substrates. These materials have excellent durability, lightweight nature, and cost-effectiveness.

Unfortunately, they are hydrophobic and extremely resistant to adhesives, thus making durable and vibrant prints difficult to achieve. These plastics have very low surface energy.

Furthermore, the manufacturing process of bottle caps introduces additional complications. Contaminants such as residues from molding agents, lubricants, and handling processes can accumulate on the surface, creating an uneven substrate that hinders ink adhesion.

The geometric complexity of bottle caps adds another layer of difficulty, as ensuring uniform treatment across such surfaces is crucial for achieving consistent print quality. These challenges necessitate innovative approaches to surface preparation to enhance adhesion and ensure durable printing.

We will cover the role of plasma cleaning in preparing the surface of bottle caps to mitigate the challenges reviewed above.

Plasma cleaning is a transformative technique for addressing the surface preparation challenges associated with bottle caps. It is a dry, non-contact process that utilizes ionized gases to clean and activate surfaces, making them more receptive to inks and coatings.

This advanced technology has proven to be a game-changer in industries where surface adhesion is critical. It effectively removes contaminants common to the manufacturing process such as oils, residues, and dust.

Additionally, it modifies the chemical composition of the surface by introducing polar functional groups, which significantly increase surface energy and improve wettability. This process ensures that inks and coatings adhere uniformly, resulting in enhanced print clarity and durability.

Plasma cleaning boosts several properties of the bottle caps, which results in enhanced print quality, increased durability, accessible eco-friendly options, consistency across batches, and improved cost efficiency.

Plasma cleaning enhances print quality by removing contaminants and increasing surface energy, plasma cleaning facilitates superior ink adhesion. It allows for vibrant, sharp, and durable prints that maintain their appearance even under challenging conditions such as exposure to moisture, refrigeration, and repeated handling.

This improvement in print quality directly impacts brand perception, as consumers associate high-quality printing with premium products. In addition to improving visual appeal, it boosts the longevity and durability of the designs.

These prints are more resistant to smudging, peeling, and fading, which is particularly important in the beverage industry, where caps are subjected to rigorous conditions during transportation and storage.

This increased durability prevents the advanced deterioration of the branded elements and keeps them intact and legible throughout the product life cycle. Plasma cleaning is more environmentally friendly than traditional surface preparation methods that rely on chemical primers or solvents, which are harmful to the environment.

Plasma cleaning eliminates the need for these hazardous chemicals, as the process ensures consistency across large production volumes, reducing the likelihood of defects and waste.

By minimizing rejections and enhancing efficiency, plasma cleaning contributes to a significant reduction in costs in the long run.

Plasma cleaning can have many applications in beverage manufacturing. It can enhance the effect of logos and branding, promotional messages, and improve the adhesion of specialized coatings.

One of the primary applications is enhanced printing of logos and branding elements. Plasma cleaning enables the creation of high-resolution designs that are visually striking and long-lasting, ensuring that the brand’s identity is solidified.

This capability is especially important for premium beverage brands that rely on superior packaging to differentiate themselves in a crowded market. It also improves clarity for promotional messages or codes inside bottle caps.

These messages are often used in marketing campaigns to captivate consumers and boost sales. Plasma cleaning ensures that these prints are clear, legible, and durable, enhancing the effectiveness of such promotional efforts.

Beyond printing, plasma cleaning can improve the adhesion of specialized coatings applied to bottle caps. These coatings may serve protective or decorative purposes, and their performance is linked to the quality of the surface preparation.

By creating a clean and activated surface, plasma cleaning ensures that these coatings adhere uniformly and effectively, enhancing both the functionality and aesthetic appeal of the caps and providing an eco-friendly alternative that aligns with growing sustainability goals in manufacturing.

The effectiveness of plasma cleaning depends on several key parameters, including the type of gas used, the duration, and the power. Oxygen is particularly effective for removing organic contaminants and activating surfaces.

The duration of plasma exposure must be carefully optimized to achieve thorough cleaning without over-treating the material. Excessive treatment can alter the mechanical properties or texture of the cap, potentially compromising its functionality.

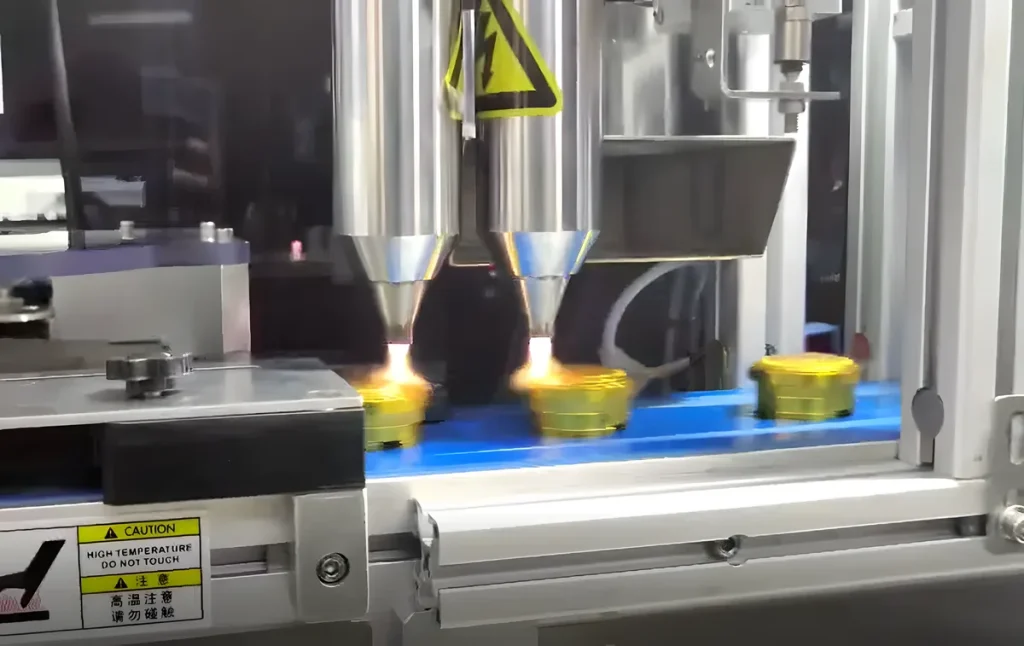

Similarly, the power output must be adjusted to ensure effective treatment tailored to the specific material and design requirements. Modern plasma cleaning systems are designed to integrate seamlessly with high-speed production lines, allowing for automated and continuous workflows.

This integration minimizes manual intervention and maximizes productivity, ensuring that the benefits of plasma cleaning are realized without disrupting the manufacturing process.

After plasma treatment, protective coatings are applied immediately to reduce the risk of contamination and ensure optimal results.

While plasma cleaning has several benefits, it also presents specific issues for you to mitigate for successful implementation.

One primary concern is the sensitivity of certain materials to over-treatment. Overexposure can alter the physical properties or surface texture, potentially compromising its strength or causing unwanted changes.

Manufacturers must carefully calibrate the duration and intensity of plasma treatment to avoid such adverse effects. This requires a deep understanding of the material properties and precise control over the plasma parameters to achieve optimal results without causing damage.

The complex geometries of bottle caps, which often include embossed designs, ridges, or intricate patterns, present another challenge. Achieving uniform plasma treatment across these irregular surfaces can be difficult, as variations in distance between the plasma source and the surface may lead to uneven cleaning and activation.

Advanced equipment with precise control mechanisms and innovative nozzle designs is often necessary to ensure consistent plasma exposure across all areas. It also considers increases in costs as the initial investment can be expensive, particularly for businesses with limited budgets.

While the long-term benefits, such as improved print quality, reduced waste, and enhanced production efficiency, often outweigh the costs, convincing stakeholders to commit to this upfront expenditure can be challenging. Demonstrating the return on investment through case studies and pilot projects is crucial for gaining buy-in.

Environmental compliance is possible, as plasma cleaning provides an eco-friendly alternative to chemical-based surface preparation methods, manufacturers must still ensure that their processes adhere to industry standards and regulations.

Proper handling of the gases and regular maintenance is essential to minimize adverse environmental issues and ensure sustainable operations. You will also need training for all personnel involved in operating and maintaining the equipment effectively, which is critical for a smooth transition.

Finally, integrating plasma cleaning into existing production lines can pose logistical challenges. High-speed manufacturing environments require seamless integration of new technologies to avoid disruptions. You must also account for potential downtime during installation and testing, and plan accordingly to minimize production delays.

Case studies from the beverage industry highlight the transformative impact of plasma cleaning on bottle cap printing.

One major beverage manufacturer implemented plasma cleaning to address issues with poor ink adhesion and inconsistent print quality. The logos remained vibrant and intact even after prolonged exposure to refrigeration and moisture. This enhanced the consumer experience while bolstering the brand’s reputation for quality.

Before adopting plasma cleaning, the company faced high rejection rates and frequent customer complaints about logos and designs fading during product use. After integrating plasma cleaning into their production line, the manufacturer observed a dramatic improvement in print durability and clarity.

Companies often emphasize promotional campaigns using bottle caps. They use printed unique codes inside the caps for consumer sweepstakes. Previously, inconsistencies in print adhesion led to smudged or illegible codes, frustrating customers and undermining the promotion’s effectiveness.

By adopting plasma cleaning, the company achieved consistently sharp and legible prints, significantly increasing consumer satisfaction and participation rates. The success of this campaign also demonstrated the reliability of plasma cleaning in high-volume, high-precision applications.

Additionally, an emerging premium beverage brand leveraged plasma cleaning to create distinctive and intricate designs on its caps as part of a rebranding initiative. The improved surface preparation allowed access to advanced digital printing techniques, resulting in eye-catching designs that set the brand apart in a competitive market.

Feedback from consumers and retailers emphasized the visual appeal and perceived quality, directly translating to increased sales and market share. These case studies highlight the potential for plasma cleaning to reduce costs by minimizing waste and defects while enhancing overall operational efficiency and customer satisfaction.

The future of plasma cleaning has advanced to accommodate better technology and sustainable alternatives. As next-generation printing techniques such as UV and digital printing gain traction, the demand for highly optimized surfaces will grow.

Sustainability will remain a key driver for plasma cleaning adoption. As manufacturers strive to reduce their environmental footprint, the eco-friendly plasma cleaning process provides a compelling alternative to chemical-based surface preparation methods. The technology’s ability to eliminate hazardous solvents and reduce waste aligns perfectly with the industry’s push toward greener manufacturing practices.

Artificial intelligence (AI) and automation allow modern systems to monitor plasma parameters in real-time, allowing for precise control and consistent results across high-speed production lines.

This level of automation further enhances uniform treatment, even in large-scale operations, solidifying plasma cleaning as an indispensable tool for the beverage industry.

Plasma cleaning can address the challenges posed by low surface energy, contamination, and complex geometries while producing superior prints on bottle caps that are vibrant, durable, and eco-friendly. If you are ready to design the best plasma cleaning set-up, contact us at Fariplasma for a free quote.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate