Due to the global push for cleaner, more sustainable energy solutions, the new energy sector is rapidly evolving. The demand for advanced material processing techniques is on the rise.

Plasma treatment is one of the leading technologies to help meet these demands by providing precise surface modifications. It plays a crucial role in increasing light absorption and improving the efficiency of batteries and fuel cells.

Some benefits of plasma technology in renewable energy applications include higher energy conversion and enhanced surface protection. In this guide, we discuss the types, applications, and benefits of plasma treatment in the new energy sector.

Plasma treatment is the process of altering the surface of a material. Because most materials contain impurities, it is essential to clean them off to apply further surface treatments. Surface treatments include painting, bonding, or gluing. Plasma is an ionized gas.

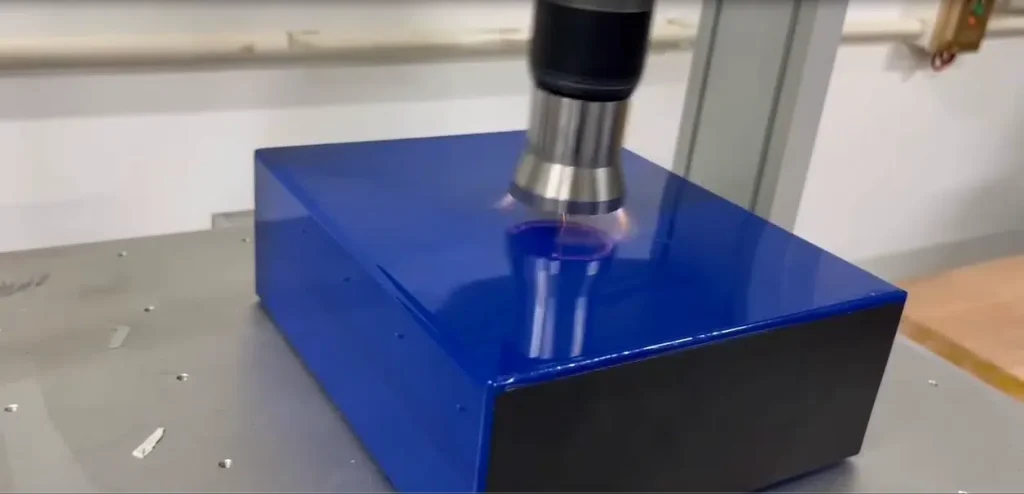

You can perform plasma treatments in a chamber or a vacuum. Air pumps out, allowing gas to flow in at low pressure. The last step is applying electrical power, which is an energy source. Plasma treatment is prevalent in many industries for coating, surface cleaning, activation, and etching.

There are various plasma treatment types in the energy sector, as seen below.

Plasma treatment enhances the performance, efficiency, and durability of devices and materials standards in the energy sector.

Surface cleaning uses ionized gas (plasma) to remove contaminants from a material’s surface. The energetic ions in plasma break down the particles into smaller molecules, such as carbon dioxide (CO₂) and water(H₂O).

The inorganic contaminants, such as metal residues and dust, dislodge from the material’s surface. There is no surface contact when you use plasma treatment for surface cleaning, preventing damage. Plasma cleaning removes contaminants from energy devices like battery components and solar panels.

The process is ideal for cleaning glass, metals, and plastics. It is suitable for industries where high surface cleanliness is essential. Plasma cleaning avoids the use of chemicals, thereby enhancing the performance and durability of energy devices.

Activation increases a material’s surface energy by adding functional groups such as carboxyl or hydroxyl. Surface activation alters the physical and chemical properties of a material, making it more receptive to coatings and adhesives.

After the surface modification, plasma activation enhances the adhesion of functional coatings like anti-reflective layers and protective coatings. Components that usually face exposure to harsh environments use plasma coatings for protection.

Plasma treatments help extend the lifespan of materials and reduce maintenance costs.

Etching is using reactive ions to remove layers from a material’s surface. High-energy ions break chemical bonds and remove atoms or molecules. They then create micro or nano-scale structures that enhance the performance of specific energy devices.

By creating textured surfaces, plasma etching improves light trapping and reduces reflection. It allows the absorption of more sunlight while enhancing the catalytic efficiency of electrodes.

One of the benefits of plasma etching is that it enhances the surface area and properties. Hence improving energy conversion and storage.

You can use the Physical Vapor Deposition ( PVD), where plasma removes material from one surface and deposits it on another. It is the ideal solution for depositing metal and ceramic coatings.

Alternatively, you can use plasma-enhanced chemical vapor deposition (PECVD). In this process, plasma enhances chemical reactions that deposit thin film.

Both processes enhance energy conversion and storage. Plasma coatings provide protective barriers, thus increasing the durability of energy devices.

Plasma treatment is essential in improving the performance and durability of various products within the new energy sector. We highlight specific products within the energy sector and the different plasma treatment applications.

The various plasma treatments offer great benefits in the new energy sector. Some of the benefits include.

You must consider your specific needs, such as the processes, the materials, and your desired outcome when choosing the suitable plasma treatment machine. The type of plasma technology is one of the key factors to consider. It can be atmospheric, thermal, low-pressure, or plasma-enhanced chemical vapor deposition.

The second factor is the machine’s compatibility with the material surface you’re working on. Plasma treatments work on glass, metal, ceramics, polymers, and composites. An ideal machine should be capable of treating different materials.

You’ll also have to consider the size and scale of your application. Atmospheric plasma treatments are ideal for large applications that require continuous processing. Compact plasma systems are better for small-scale operations.

Surface treatment capabilities will also determine the ideal plasma treatment machine. For surface cleaning, you’ll need a machine with solid cleaning capabilities. Surface activation requires a machine that can activate surfaces chemically without damaging the materials.

As new technologies evolve, future trends in plasma treatment are expected to emerge. Future developments will concentrate on low-temperature plasma treatments more compatible with temperature sensitive materials. It will lead to broader applications such as portable electronics.

Green plasma technologies that minimize environmental impact will emerge. Future plasma treatments will consume less energy by replacing traditional chemical methods in the production of energy devices.

Plasma treatment plays a critical role in advancing the new energy sector by enabling enhanced performance, durability, and efficiency. Processes such as thin-film deposition, surface activation, and etching develop high-performance, sustainable energy solutions. Plasma technology has the ability to enhance various energy applications, making it critical for the future of clean energy. For plasma solutions tailored to meet your needs, contact Fari Plasma.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate