In today's manufacturing landscape, surface quality directly impacts product reliability and performance. Whether you're in semiconductors, aerospace, automotive, or medical device manufacturing, achieving optimal adhesion between materials is crucial for success. One of the most effective yet often misunderstood technologies for improving adhesion is plasma cleaning.

At Fari Plasma, we've spent years perfecting plasma treatment systems that help manufacturers eliminate surface contamination and dramatically improve material bonding. This comprehensive guide will walk you through everything you need to know about plasma cleaning, how it works, and why it's becoming essential in modern manufacturing processes.

Plasma cleaning is a dry, chemical-free surface treatment process that removes contaminants, oxides, and organic residues from material surfaces using ionized gas. Unlike traditional wet chemical cleaning methods, plasma cleaning is precise, environmentally friendly, and leaves no residual waste on the treated surface.

Think of plasma as the fourth state of matter—beyond solid, liquid, and gas. When energy is applied to a gas, electrons separate from atoms, creating a mixture of ions, electrons, and neutral particles. This energized state allows plasma to interact with surface contaminants in ways that conventional cleaning methods simply cannot match.

In practical terms, plasma cleaning works like this: materials are placed inside a chamber where controlled plasma is generated. The active species in the plasma—including ions, radicals, and UV radiation—bombard the surface, breaking down contaminants at the molecular level. The result? An exceptionally clean, reactive surface ready for bonding, coating, or further processing.

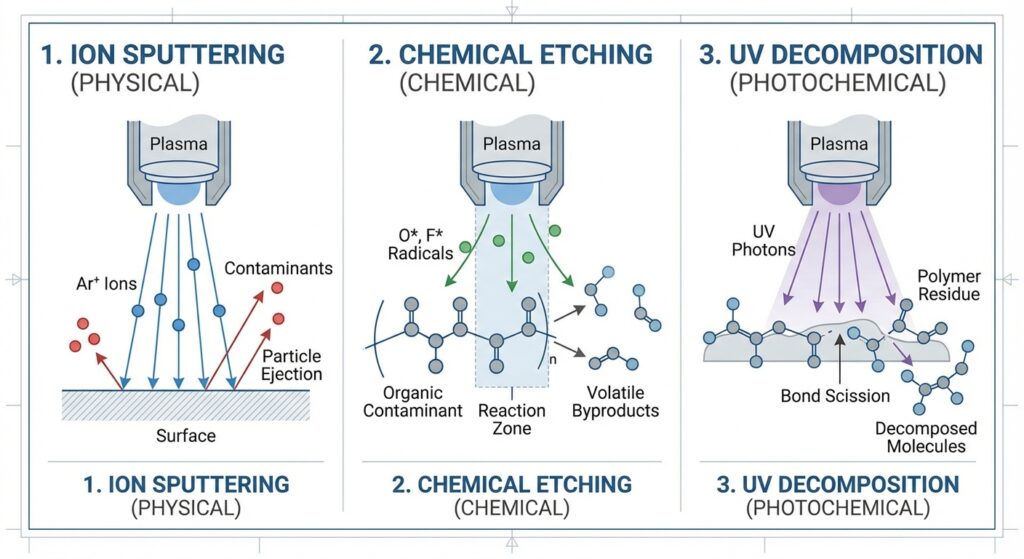

To truly appreciate plasma cleaning, it helps to understand the underlying mechanisms:

When energetic ions strike the surface, they physically remove layers of contamination through a process called sputtering. This is particularly effective for removing metallic oxides, fingerprints, dust, and other particulate matter.

The reactive radicals and ions in plasma engage in chemical reactions with surface contaminants. These reactions break molecular bonds and convert contaminants into gaseous byproducts that are evacuated from the chamber. This process is especially effective for removing organic residues like oils, resins, and polymeric coatings.

The UV radiation emitted during plasma generation helps break down organic molecules through photochemical processes, complementing the physical and chemical cleaning mechanisms.

Beyond cleaning, plasma treatment actually creates a more reactive surface. This increased surface energy makes the material more receptive to adhesives, coatings, and other bonding agents—a critical advantage for adhesion improvement.

You might wonder: "Why not just use conventional cleaning methods?" The answer lies in the limitations of traditional approaches:

Wet Chemical Cleaning:

Mechanical Abrasion:

Solvent Cleaning:

Plasma cleaning overcomes all these challenges. It's thorough, fast, clean, and environmentally responsible.

Adhesion failure is one of the most costly problems in manufacturing. Whether you're bonding two materials with an adhesive, applying a protective coating, or depositing thin films in semiconductor processing, poor adhesion leads to:

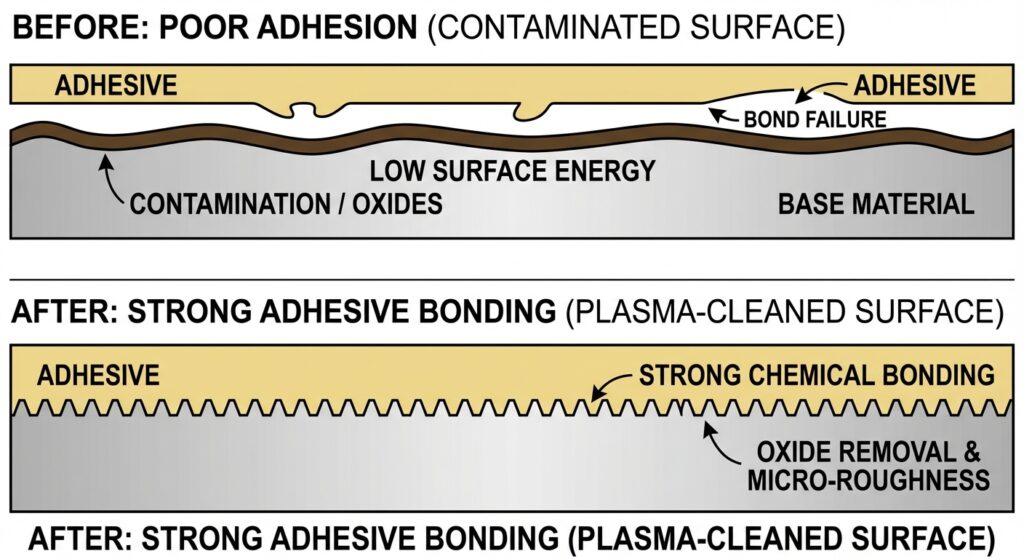

The root cause of adhesion problems is almost always the same: contamination on the surface. Even microscopic layers of dust, grease, oxides, or moisture create a barrier between materials, preventing true chemical bonding.

This is where plasma cleaning becomes invaluable. By removing these barriers at the molecular level and creating a highly reactive surface, plasma cleaning ensures that adhesives, coatings, and bonding materials make direct contact with the substrate material itself.

The adhesion improvement mechanism works through several complementary processes:

Plasma eliminates all types of surface contamination—organic and inorganic alike. This creates a clean surface where adhesion can actually occur.

On metal surfaces, oxide layers dramatically reduce adhesion strength. Plasma selectively removes these oxides, exposing the reactive base material underneath.

Plasma treatment dramatically increases surface energy (wettability), making the surface much more receptive to adhesives and coatings. In quantitative terms, surface energy can increase from 20-30 mDyne/cm to 70-80 mDyne/cm or higher—a transformative change.

Plasma creates a micro-roughened surface at the molecular level, increasing the contact area available for bonding without causing the macro-level damage associated with abrasion.

The plasma process creates reactive chemical groups on the surface that can form stronger chemical bonds with adhesives and coatings.

The versatility of plasma cleaning makes it valuable across numerous sectors:

In semiconductor fabrication, plasma cleaning is essential for:

Medical device manufacturers rely on plasma cleaning for:

These industries benefit from plasma cleaning for:

PCB manufacturers use plasma cleaning for:

In packaging applications, plasma cleaning improves:

Different manufacturing needs require different plasma technologies. At Fari Plasma, we offer several approaches:

These systems operate below atmospheric pressure and are ideal for:

These systems operate at normal air pressure and offer:

For demanding semiconductor and advanced manufacturing applications, we develop customized plasma systems tailored to specific process requirements.

How do you know plasma cleaning is working? Several quantifiable measurements demonstrate effectiveness:

Reduced contact angles indicate increased surface energy and wettability—reliable indicators that plasma treatment has improved the surface.

Adhesive bond strength can be measured using standard peel tests, with results typically showing 50-300% improvement after plasma treatment.

For structural adhesives, lap shear tests quantify the adhesive bond strength improvements.

Cross-hatch adhesion tests and other standardized methods measure coating adhesion improvements.

Effective plasma cleaning requires attention to several parameters:

The optimal parameters depend on your specific material, contaminant type, and adhesion requirements. At Fari Plasma, our team helps customers develop customized process recipes that maximize adhesion improvement while protecting material integrity.

Beyond performance benefits, plasma cleaning offers significant environmental and safety advantages:

While plasma cleaning is powerful, successful implementation requires understanding potential challenges:

Some materials may be damaged by plasma treatment. Polymers, for example, require careful parameter selection to avoid degradation.

Achieving consistent results requires proper equipment calibration, regular maintenance, and process control.

Quality plasma equipment represents a significant capital investment, though ROI typically comes quickly through improved product quality and reduced defects.

Operators need proper training to maximize the benefits of plasma technology.

As manufacturing demands become more stringent, plasma cleaning technology continues to evolve:

Plasma cleaning represents a fundamental advancement in surface treatment technology. By providing superior contamination removal, surface activation, and adhesion improvement, plasma cleaning addresses one of manufacturing's most persistent challenges.

Whether you're working in semiconductors, aerospace, medical devices, or any field where adhesion quality matters, plasma cleaning offers measurable improvements in product reliability, performance, and longevity.

At Fari Plasma, we're committed to providing manufacturing partners with cutting-edge plasma treatment systems that deliver consistent, reproducible results. Our plasma cleaners, plasma treatment systems, and specialized semiconductor equipment help manufacturers achieve adhesion excellence while maintaining cost efficiency and environmental responsibility.

If you're looking to improve adhesion performance in your manufacturing process, now is the time to explore how plasma cleaning can transform your results.

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate