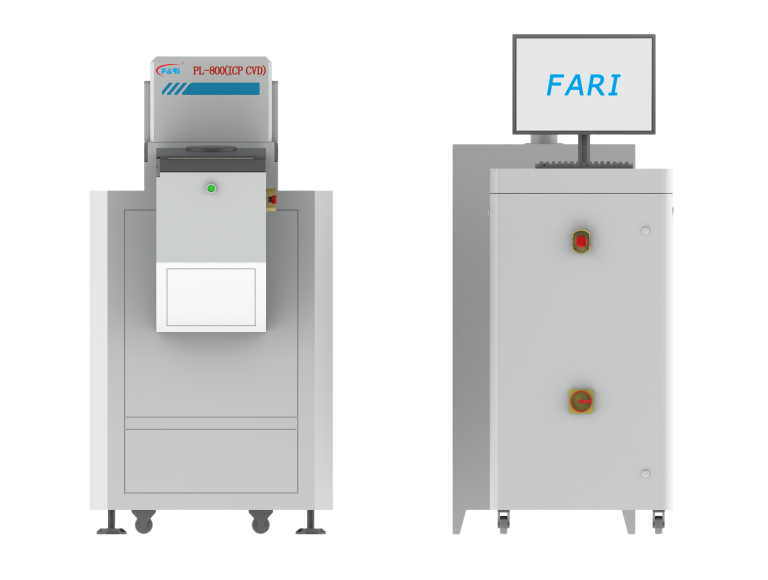

High-density ICP CVD dual-chamber system for deposition of SiN, SiO2 and a-Si films. Delivers uniform, reproducible thin films and advanced composite deposits for semiconductor, solar and related industries.

| System Type | Inductively Coupled Plasma Chemical Vapor Deposition (ICP-CVD) |

| Configuration | Dual-chamber design for parallel processing and higher throughput |

| Target Films | Silicon nitride (SiN), silicon dioxide (SiO2), amorphous silicon (a-Si) and composite deposits |

| Main Components | Reaction chambers, vacuum system, gas delivery system, RF power supply, and integrated control system |

| Plasma Source | Inductive RF excitation producing high-density plasma and abundant reactive species |

| Primary Functions | Thin film deposition, surface modification, and composite material growth via plasma-driven chemistry |

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate