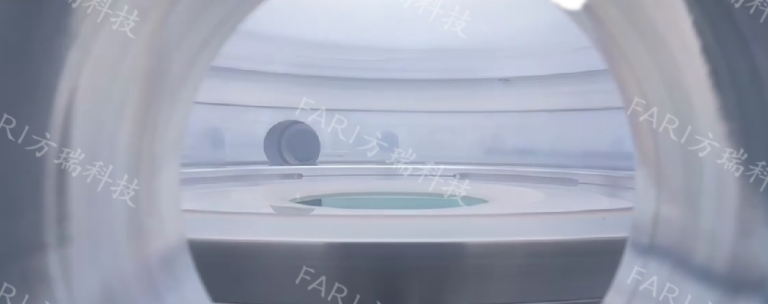

The PD-200 ICP plasma residue removal system uses a 13.56 MHz RF source (2 kW) for efficient photoresist and residue ashing. Supports multi-wafer handling for 2/4" wafers, temperature control up to 250°C and tight uniformity ≤5%.

| Model | PD-200 |

| Plasma Source | RF 13.56 MHz |

| RF Power | 2 kW |

| Applicable Wafer Sizes | 2", 4", 6", 8" |

| Batch Handling | Multi-wafer (only for 2" and 4" wafers) |

| Dimensions (L×W×H) | 673 × 1455 × 1695 mm |

| Chamber Configuration | Transfer chamber + process chamber |

| Process Temperature Control | 50–250 °C |

| Uniformity | ≤5% (edge excluded 10 mm, 5-point measurement) |

| Plasma PR Removal | ≤90 °C; 50–100 nm/min; uniformity ≤5% (5-region test) |

| High-temperature Ashing | ≤250 °C; 3000–5000 nm/min; uniformity ≤5% (5-region test) |

| System Control | FR control system (FR system / FangRui) |

| Automation Level | Manual + semi-automatic |

| Electrode Cooling / Chiller | Electrode cooling FR-600A-H |

Mox dicta finierat, multitudo omnis ad, quae imp erator voluit, promptior laudato consilio consensit in pacem ea ratione maxime percita, quod norat expeditionibus crebris fortunam

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate