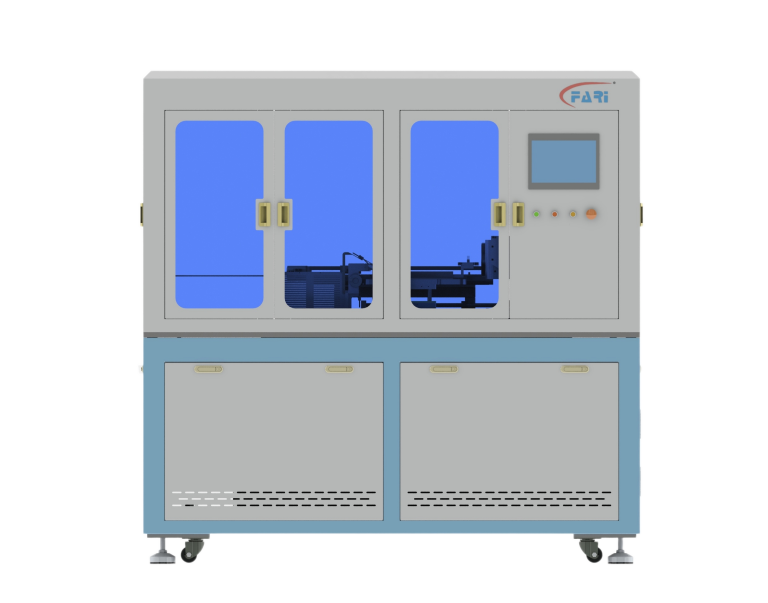

Compact online plasma cleaner tailored for lead-frame and LED-frame processing. Provides surface-only modification for metals, plastics and glass with stable, controllable, energy-efficient, dry treatment that requires no chemicals.

| Voltage | AC 220V 50Hz |

| Plasma Power | 600 W |

| Vacuum Chamber Volume | 30 L |

| Gas Lines | 2-channel mass flow controllers |

| Gas Pressure | 0.6 MPa |

| Throughput | 320 pcs/h (4 magazines) |

| Dimensions (L×W×H) | 1900 × 1100 × 1800 mm |

| Utilization Rate | 95% |

| Operating Temperature Range | -10 °C to 50 °C |

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate