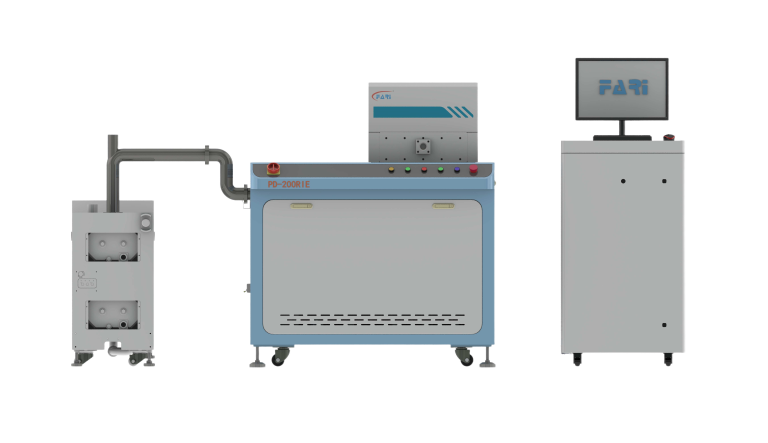

RIE Plasma Resist Stripping System delivers controlled, uniform plasma-based resist and contamination removal for semiconductor, medical, automotive and energy applications, improving surface cleanliness and adhesion.

| Chamber Size | Ø200 mm internal diameter (approx.) |

| RF Power Range | 0 – 300 W, digitally adjustable |

| RF Frequency | 13.56 MHz standard |

| Process Gases | O2, Ar, CF4, CHF3 (configurable mixtures) |

| Pressure Range | 1 – 1000 mTorr (0.13 – 133 Pa) |

| Maximum Part Size | Up to 200 mm diameter or equivalent |

| Typical Cycle Time | Process-dependent; typical 1 – 15 minutes |

| Temperature Control | Ambient to 200 °C (optional heater) |

| Control System | Industrial PLC with color touch screen |

| Power Requirements | AC 220 V ±10%, 50/60 Hz, ~2 kVA |

| Dimensions (W×D×H) | 800 × 700 × 1400 mm (approx.) |

| Weight | Approx. 150 kg |

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate