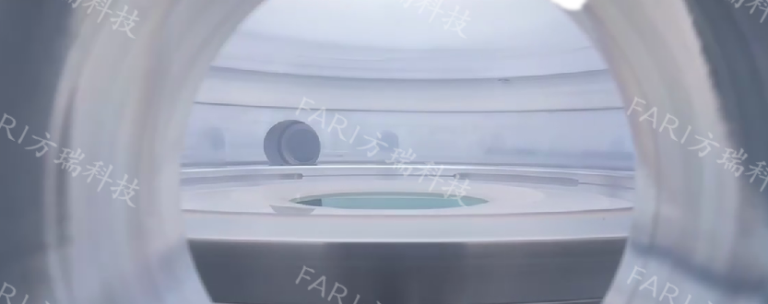

The SD-300 is an ICP-based photoresist stripper designed for high-efficiency removal of photoresist, organic residues and nanoscale contaminants in advanced semiconductor, packaging and display processes. It offers eco-friendly operation, flexible process control and high uniformity for reliable production.

| Model | SD-300 |

| PlasmaSource | RF 13.56 MHz |

| RFPower | 2 kW |

| WaferCompatibility | 2, 4, 6, 8 inch |

| BatchProcessing | Multi-wafer (multi-wafer processing only for 2" and 4" wafers) |

| Dimensions | 673 × 1455 × 1695 mm (L × W × H) |

| ChamberConfiguration | Load lock + process chamber |

| ProcessTemperatureRange | 50–250 °C |

| Uniformity | ≤5% (edge exclusion 10 mm, 5-point measurement, Max-Min/(2*mean)) |

| LowTemperatureResistRemoval | Process temperature ≤90 °C, removal rate 50–100 nm/min, uniformity ≤5%, 5-area thickness test |

| HighTemperatureAshing | Process temperature ≤250 °C, removal rate 3000–5000 nm/min, uniformity ≤5%, 5-area thickness test |

| ControlSystem | FR system (FangRui) |

| AutomationLevel | Manual to semi-automatic |

| Chiller | Electrode cooling FR-600A-H |

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate