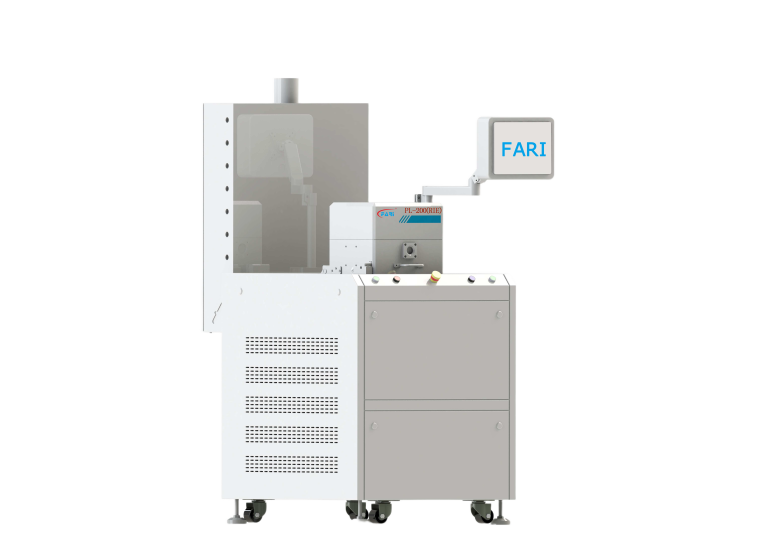

The FR-G200 single-chamber RIE reactive ion etcher delivers precise, anisotropic dry etching for silicon, SiN and SiO2 with high selectivity and repeatability for semiconductor, MEMS and nano-fabrication.

| Model | FR-G200 (RIE) |

| Etch Technology | Reactive Ion Etching (RIE) |

| Chamber Type | Single-chamber, parallel-plate configuration |

| Supported Materials | Silicon (Si), Silicon Nitride (SiN), Silicon Dioxide (SiO2) and common semiconductor films |

| Wafer / Substrate Size | Up to 200 mm |

| RF Power | Adjustable, 0–600 W |

| RF Frequency | 13.56 MHz |

| Vacuum Range | ≈1x10^-3 to 1x10^-1 Torr (typical process range) |

| Process Gases | CF4, SF6, O2, CHF3, Ar and other specialty chemistries |

| Etch Mode | Anisotropic, ion-assisted chemical etching |

| Control Interface | Digital process controller with recipe storage |

| Safety & Diagnostics | Interlocks, plasma monitoring and fault indicators |

English

Japanese

Korean

Rogatus ad ultimum admissusque in consistorium ambage nulla praegressa inconsiderate